EddieWalker

Epic Contributor

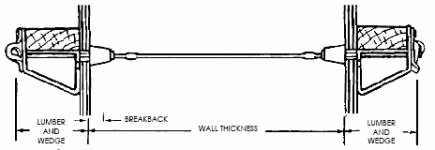

Wow!! This sure went off track. I apparently did not word my question correctly, but the answer appears to to be that either PT or regular plywood will work for me. So let me try again to describe what I'm doing. I'm putting a storm shelter inside my house. First of all there is already wood framed walls in place. I want to use the studs and nail 3/4" plywood to it as one side of the forms and use the form ties to provide the proper spacing of the plywood. Once the concrete is poured I will only have access to one side of the wall, so the forms on one side will have to remain in place. My concern had more to do with long term rot since the wood will always be in contact with the concrete. Then on the side I do have access to, since the plywood is already in place and the lath is the same thickness, why not just leave the plywood in place as the lath and I can mount anything anywhere on the wall. There's the moisture issue again. This was intended more as a question about after the concrete is poured and now ready to remove the forms, what happens if I don't. Sorry for the misunderstanding.

Sounds like I will be fine using regular 3/4" plywood for the forms and leaving it in place permanently (with the addition of the proper bracing with 2x4s).

Since you are building a safe room, have you looked at this page from FEMA on safe rooms? https://www.fema.gov/media-library-...709/FEMA_P-320_2014-ConstructionPlans_508.pdf

One of my future projects is to build a safe room that will also act as a walk in gun safe. I'm planning on doing it just like they say on the FEMA plans. I think that it's well thought out and not very hard to do. Removing part of the existing foundation will be the most labor intensive, but it's not hard to cut concrete and jack hammer it out. Bending and tying rebar is straight forward, as is stacking block. The roof is going to be the toughest, and when I do it, I'm planning on leaving the plywood on it after pouring the concrete. I'm unsure if I will add plywood to the walls, or just leave them alone, or paint them white to make it brighter in there.

There are several sources for "gun safe" style doors. Prices seem to be from $3,500 on up. I don't think it's worth the effort and price of materials to try and make a door myself.

If you do this, please start a thread on your progress. I'm very interested in what you do and learn along the way.