Sorry for my slowww response, been kinda busy with medical junk for a month. Back in action now. Still slow, but moving in the right direction.

No, the cylinder stays inside the frame and all plumbing is done underneith. So my mods of moving the control to the front end simply requires the right-angle fittings on the cylinder to be oriented facing forward instead of backwards.

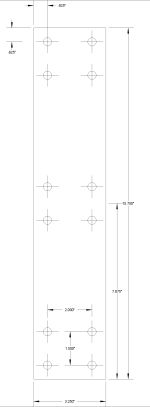

Yes, pic #2 is a u-bracket. I made three of them. Their function is to keep the splitter hydraulic fittings and hose from resting on the ground upon it is lowered all the way. The u brackets also keep the hose suspended up under the unit, so it doesnt sag down. The brackets bolt onto existing holes.

I can not be sure what your cycle time will be, but be sure to let us know after you measure it. Mine is fine for me, and I guess I have 9 gpm on the implement pump.

Finally, I went ahead and moved the control valve to the opposite side (now on the right side of the tractor) of the splitter, keeping it up at the front end of the splitter, but spinning it around so the lever is foreward of the control valve. This keeps the lever and linkage further from the splitting operation, both foreward and upward. It also required one new hose, shorter by a couple feet. Now, with the control on the right side of the tractor, I can stand on the right side to operate it, and without walking around the tractor or climbing onto the tractor, I can reach the three-point lift lever and engine throttle lever. This helps one-man operation greatly. I swapped the work tables then, so the smaller table is on the side I stand up next to. The tables just pin in place, so that change was trivial.

I finished a special skateboard for it too, for storage. Built with angle iron and casters, it allows the splitter to be rolled off into the corner when not in use.

I should be able to get some pictures of this stuff eventually.