SpudHauler

Gold Member

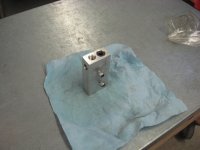

Is a pressure relief block like this one pictured here required when using a 12v selector valve?

Or does the selector valve, from Surplus Center, have it's own release?

I bent one of my bolts holding the swing cylinders and am wondering if it was because i did not re-install the relief block when I installed the selector valve.

The selector valve gives me the up/down and left/right using one spool on my RTV1100 Kubota.

Third picture is how it is connected out front and on the spool lever I have a push button switch for the left/right cylinder activation.

Or does the selector valve, from Surplus Center, have it's own release?

I bent one of my bolts holding the swing cylinders and am wondering if it was because i did not re-install the relief block when I installed the selector valve.

The selector valve gives me the up/down and left/right using one spool on my RTV1100 Kubota.

Third picture is how it is connected out front and on the spool lever I have a push button switch for the left/right cylinder activation.