<font color="blue">

It's usually due to poor quality insulation on the terminal. Most "automotive" style terminals use a hard plastic insulation which is more likely to crack or harden. These are usually dark blue (14-16ga) or dark yellow (10-12ga). The color is opaque. Usually the translucent colored ones (light blue/yellow/pink) use a softer, more pliable insulation. </font>

Yep - nylon vs. no-name plastic. With crimp connectors, it's worth paying for the better name brands like 3M. Get the translucent stuff - nylon. Better quality, and you can see what you are doing.

Inside a car, weather & corrosion is not much of an issue. On a tractor, it sure might be. Solder & heat shrink is BEST, but a good crimp and heat shrink is also very good. You want the type of heat shrink that gets gooey on the inside when you heat it. Not all does that.

Second the motion on AMP, Paladin, or Klein. Cheap tools are false economy. I'm not familiar with the Snap-On, so have no opinion.

Someone mentioned getting the connector in the right direction - this is critical, and very often overlooked.

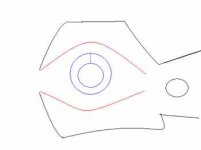

If you look into the end of a crimp fitting, you'll see that it is a rolled tube. There is a seam running the length of it. You want that seam at 12 or 6 o'clock with respect to the crimpers. That is, you want the crimpers jaw to come down directly on the seam. Otherwise, the seam is likely to split open, and you'll have a MUCH weaker crimp. You DON'T want the seam pointing to the jaw opening, or back at the crimper's joint.

Attached is a pathetic attempt to illustrate this. The blue is the connector, seen from the end (and without insulation). The red are the crimper's working surfaces. It's a lousy drawing, but perhaps it's enough to show what I'm talking about.