ArlyA

Super Member

- Joined

- Mar 18, 2016

- Messages

- 9,551

- Tractor

- Polaris Boss 6x6 with pods (tracks) Center actuating lawn mower by Husky

electric PTO clutch and shaft size help!

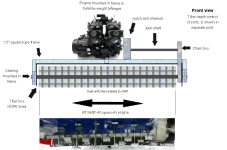

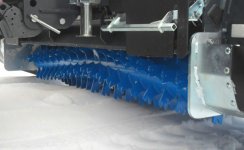

I'm assembling a mini tiller what is used within the cross country ski industry to chew up hardened snow. There are a few made in the EU, but these do no fill the needs here in North America and are toooooooo narrow or under powered in general. The one I've been asked to assemble with be 6ft wide and be powered by a v-twin engine, putting out 37 or so HP. The HP per foot is already been established by the alpine industry, so I'll stick with those approximate numbers. The engine's we're looked at come either with a 1 and 5/16 or 1 and 1/8 output shafts.

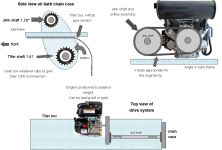

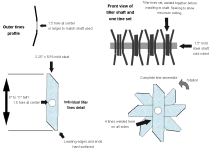

In the below print, you can see a jack shaft that bring the power out to the implements end and connect to chain box that will of course run the tiller. The tiller will need to be ran at 1000 RPM, give or take so will need be a 3 to one reduction. Off the engine, we've like to use a couple of 5vx belts to power the jack shaft off the engine. Here on the jack shaft, we'd like to utilize an electric PTO clutch that can used with dual, 5vx belts. Two questions for you mechanical gurus here are below.

Would a 1 and 1/8 size mild steel jack shaft be sufficient if its 2 to 4ft long? Engine will be position so as to balance the implements weight so the jack shafts length is not know at this time.. An where can we find a PTO clutch we can use and has 2 belts and can be used with a 37 HP engine. Obviously it needs to be 12 volt and no brake is needed. Start up will be at idle or low RPM and system inertia is hard for me to describe. I guess it would be like a 6ft wide dirt tiller. Options????

I'm assembling a mini tiller what is used within the cross country ski industry to chew up hardened snow. There are a few made in the EU, but these do no fill the needs here in North America and are toooooooo narrow or under powered in general. The one I've been asked to assemble with be 6ft wide and be powered by a v-twin engine, putting out 37 or so HP. The HP per foot is already been established by the alpine industry, so I'll stick with those approximate numbers. The engine's we're looked at come either with a 1 and 5/16 or 1 and 1/8 output shafts.

In the below print, you can see a jack shaft that bring the power out to the implements end and connect to chain box that will of course run the tiller. The tiller will need to be ran at 1000 RPM, give or take so will need be a 3 to one reduction. Off the engine, we've like to use a couple of 5vx belts to power the jack shaft off the engine. Here on the jack shaft, we'd like to utilize an electric PTO clutch that can used with dual, 5vx belts. Two questions for you mechanical gurus here are below.

Would a 1 and 1/8 size mild steel jack shaft be sufficient if its 2 to 4ft long? Engine will be position so as to balance the implements weight so the jack shafts length is not know at this time.. An where can we find a PTO clutch we can use and has 2 belts and can be used with a 37 HP engine. Obviously it needs to be 12 volt and no brake is needed. Start up will be at idle or low RPM and system inertia is hard for me to describe. I guess it would be like a 6ft wide dirt tiller. Options????

Attachments

Last edited: