LD1

Epic Contributor

I am not sure why the reciever design is needed. What do you plan on doing with the frame with the forks off?

Thanks for all the great information.

I did not expect that the loss of strenght would be that great.

With the limited lift capacity of my 30hp Kubota B7800, I am attempting to

eliminate weight wherever possible. Around 760 lbs. on the FEL and 1650 on the 3PH.

I also like the profile of the 3 x 1.5" steel for the forks.

What if I milled some quality/straight grain lumber and inserted the lumber tightly into

the open cavity in each tine. Straight grain lumber can be good and stiff and add some

addtional strength to the steel? Bad idea?

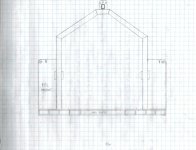

LD1-I am planning to put 3 or 4 receivers on each side in order to gain adjustability. Being that this set of forks is going to be mountedI am not sure why the reciever design is needed. What do you plan on doing with the frame with the forks off?

The 2x2" forks insert into 4 1/2" cut pcs of 2.5 x2.5" x 1/4" tubing, acting as receivers. I there any way, or need, to improve upon this receiver design?

The wood will provide very little bending stiffness even if attached to the steel continuously along the length. Two reasons... first the Modulus of Elasticity (stiffness... maybe 20 to 1) is much lower for wood than Steel and second, the wood is near/at the neutral axis of bending. This is why I beam shapes are designed/used. They have most of their material at the farthest from the center/nuetral axis of the cross section. I beams are great in bending but not torsion... closed walls such as tubes are much better in those cases.What if I inserted 2 bolts through them to keep them from moving?

I have a B2710 & don't know the difference betw 2710 and 7800, might be identical for all I know. I'm glad you posted this because I will build something similar, soon - maybe tomorrow. You've inspired me, maybe I will do a little tine engineering.

Here's my thoughts.

I'd use 3 or 4 sockets too. I'd use it for a log skidder, and with a receiver hitch, to move trailers around. I have other uses too, plans for a clamping sawbuck too.

That is made for a large tractor. It would dominate a B-series. I would make it smaller, lighter. I would definitely make the times removable, with the a socket arrangement. When you add 43 inches to the length of a compact tractor, they are going to be in the way, you will wipe stuff out! They will be as far back from the rear axle as your radiator guard up front. You will be very happy to have them removable, stowable. Otherwise you will be inclined to remove the whole thing. Then ------ where is it when you need it? ---- Well it's setting way over there, because it's too darn big, awkward and too heavy too. If you make the tines removable your device will remain on the tractor, ready for use anytime. And when off the tractor, it can be leaned against the wall not taking up as much space as a whole pallet.

I guess we are not going to be lifting over a ton

on these machines.

Build the frame out of aluminum square tube, and use steel for the forks.Where can we cut out weight?

How are you planning to scale it back? Where can we cut out weight?

Heres some engineering for ya. You've already moved on but the engineer will still flog you with numbers. :laughing:

snip"

Or, if you're me and you want things shiny AND stout :laughing: (and don't care much about the weight), you buy 2.53" square tube with .250 wall (scroll down the size list, you'll see it)

Ram Steelco Inc. - Salem, Oregon | Steel Sales, Metal Sales and Metal ProcessingThe stuff I buy is about the middle of that page, cost is about the same as 2.5" but it fits with no hangups - the normal 2.5" stuff has the weld seam so you need a bit of slop for things to fit... Steve[/QUOT