Deerherd

Veteran Member

- Joined

- Apr 9, 2012

- Messages

- 1,064

- Location

- Upstate, NY

- Tractor

- LS P7030 CPS, 2016 Bobcat E42, Ferris IS3100z w/37 HP Kawasaki

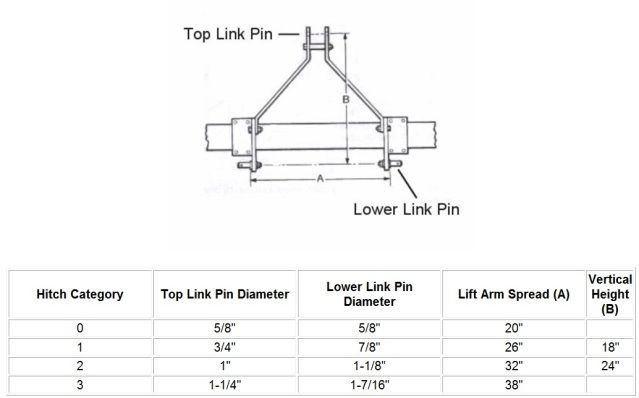

Great thread. I purchased a Woods QH (rebranded speeco) to use on my Woods implements that I just purchased. I could tell just by looking at it things needed to be changed but my dealer had no clue. I called Woods and they gave me part numbers for bushing kits for the different implements. For the Bushbull BB72X it's 1027549, Grading Scraper GS72C it's 1003832 and for the snow blower they said they would have to get back to me. So far they haven't. And oh by the way, they are out of stock on the kits. I think I can get the bushings made locally if I can find out the correct size.