moose13

Bronze Member

Thanks for the new replies!

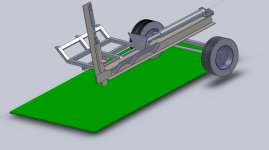

I know there is little to no savings here, but i will be honest with ya, i kicked a few tires on the big box store models and was not impressed at all. I am sure they would work for years to come and do the job. But, i prefer to build my own. I enjoy doing the work and already have axle, tires, I beam, jack and hitch. + any misc steel i would need. More "older" welding rod than i could ever burn. I do need to fabricate a tank but already have the steel and a plan. I am a bigger guy, 6'5 325 and many of the store bought ones are just too short. Like i said i enjoy the work and am out of projects, so why not.

I agree on the wedge design Oliver, Thanks!

I know there is little to no savings here, but i will be honest with ya, i kicked a few tires on the big box store models and was not impressed at all. I am sure they would work for years to come and do the job. But, i prefer to build my own. I enjoy doing the work and already have axle, tires, I beam, jack and hitch. + any misc steel i would need. More "older" welding rod than i could ever burn. I do need to fabricate a tank but already have the steel and a plan. I am a bigger guy, 6'5 325 and many of the store bought ones are just too short. Like i said i enjoy the work and am out of projects, so why not.

I agree on the wedge design Oliver, Thanks!