westcliffe01

Veteran Member

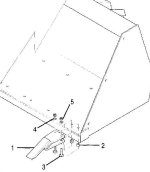

I find this an embarrasing subject, since tight bolts are in some ways part of working with heavey equipment, but here goes: The teeth on my Bobcat B200 loader bucket are bolted on and every attempt to remove the bolts so far has failed.

Since I am working with landscaping on my property, having the teeth on the loader bucket is actually a hinderance instead of a help. I don't need the teeth to move dirt or gravel and it makes smoothing surfaces much more difficult. I also have a few loose teeth on the backhoe that I want to tighten up before things deteriorate further.

Countersunk allen head bolts are used and even if I use a 4 ft cheater bar on the end of the correct size wrench on the nut end, I find it impossible to do anything but rotate the nut and bolt together when trying to loosen them. The allen socket is not that big (much smaller than the nut which is almost 1" AF) so I am afraid to put too much of a load on it in case they strip out.

Anyone know whether special interference fit nuts are used for this application ? Is it customary to have to cut off the nuts to remove teeth ? Any other hints ?

Since I am working with landscaping on my property, having the teeth on the loader bucket is actually a hinderance instead of a help. I don't need the teeth to move dirt or gravel and it makes smoothing surfaces much more difficult. I also have a few loose teeth on the backhoe that I want to tighten up before things deteriorate further.

Countersunk allen head bolts are used and even if I use a 4 ft cheater bar on the end of the correct size wrench on the nut end, I find it impossible to do anything but rotate the nut and bolt together when trying to loosen them. The allen socket is not that big (much smaller than the nut which is almost 1" AF) so I am afraid to put too much of a load on it in case they strip out.

Anyone know whether special interference fit nuts are used for this application ? Is it customary to have to cut off the nuts to remove teeth ? Any other hints ?