handirifle

Veteran Member

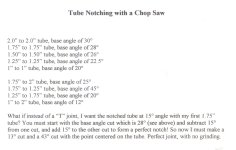

Since I welded up my trailer with round tubing, I spoke with someone (online or in person, not sure) and they told me about how to easily "notch" tubing with a cutoff saw, by setting it at "?" degree and cutting both side, and it's a near perfect fit. This is for a 90 deg angle only. Anyone know this trick and what the setting should be? I realize this is not a perfect deal but it has to be better than my last endeavor. I do not want to buy a tubing notcher, too slow.