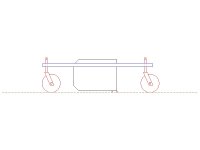

I also agree with Shaley, you won't need the front wheels on your box. Once the rear wheels are in place, you will be able to VERY accurately control the depth of cut with the 3PH toplink. The rear wheels of the tractor will do the same thing that the front wheels in your pic would do. The 3PH structure holds the impliment at the same angle regardless of 3PH height. With the rear gauge wheels in place, you run the 3PH in float so the impliment is always at it's lowest possible position(rideing on those rear wheels. If you want less cut, you lengthen the toplink which raises the front of the box scraper. Since the wheels are touching the ground in the back, they are the pivot point and everything forward of them, including the blade will move upward as you lengthen the toplink.

On your drawing, unless you add some easy method to jack up the box between the wheels, it will be difficult to transport without cutting inplaces you don't want it to cut. By using the 3PH, you can build this simpler and you will be easilly able to raise and transport or turn around without tearing into something you maybe don't want to.

Good Luck.