Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,197

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

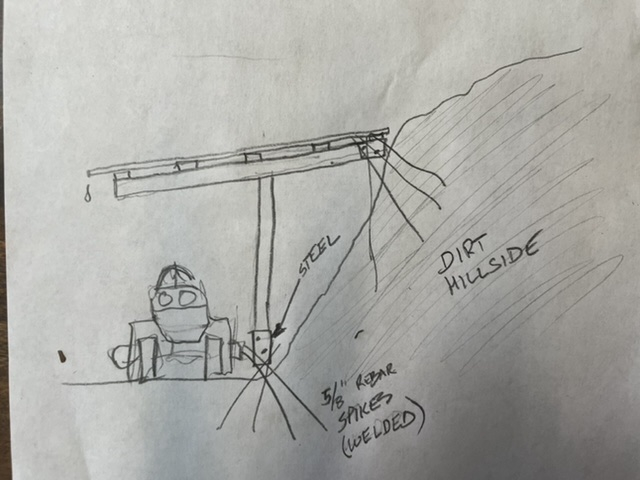

What do you think of this?

I know you value the shelter, as will My Deere….

I pounded rebar spikes into the dirt and welded a steel bracket on.

Then bolted a cedar board to the bracket.

Its cantilevered.

It doesn't snow like the old days.

We got 9” of snow last winter. Got just 2 inches this winter.

I suppose if its going to snow I hope to remember to prop it up ahead of time.

Bracket welded to rebar spikes.

They’re 5/8” rebar, 4feet long,

Splayed out like the roots of a steel stump.

Thats a 120v electric demolition hammer.

It cost less than $200.

Unlikely that I will ever have to use it all day long so I think it will last (for me).

Pounding the spikes in with a 5 lb hammer was laborious but like butter with the demo hammer.

OK one rafter down, one to go.

That’s how far along I am at the moment.

Gotta do it one more time then put some purlins on

I know you value the shelter, as will My Deere….

I pounded rebar spikes into the dirt and welded a steel bracket on.

Then bolted a cedar board to the bracket.

Its cantilevered.

It doesn't snow like the old days.

We got 9” of snow last winter. Got just 2 inches this winter.

I suppose if its going to snow I hope to remember to prop it up ahead of time.

Bracket welded to rebar spikes.

They’re 5/8” rebar, 4feet long,

Splayed out like the roots of a steel stump.

Thats a 120v electric demolition hammer.

It cost less than $200.

Unlikely that I will ever have to use it all day long so I think it will last (for me).

Pounding the spikes in with a 5 lb hammer was laborious but like butter with the demo hammer.

OK one rafter down, one to go.

That’s how far along I am at the moment.

Gotta do it one more time then put some purlins on

Attachments

Last edited: