Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 7,047

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

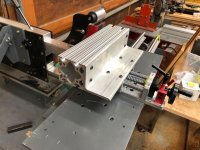

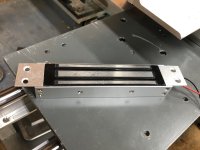

I got the sliding table set up to work with the grinder in the horizontal position. It removes material very fast and accurate. I debated making a fine adjustment mechanism to move the table toward and away from the belt, but decided for starters to just move the tool rest arm in and out. That works but is too clunky. So the next step is to make a screw in/out adjuster.

Totally looking forward to what you come up with for feed adjustment. Again, nice work so far

And I know you did it a while back but I love your vertical to horizontal mechanism.