sdboers

Bronze Member

Hey folks,

I know it's likely been covered many times before - but I'm clearly searching for the wrong terms... I'm looking for information on hooking up snow plow hydraulics (single action cylinders) to the front of my tractor. I've got three scenarios I'm considering from cheapest and most manual, to most expensive and most convenient. Not sure if I've got this right, so any information would be appreciated.

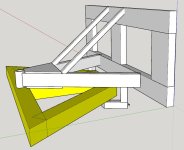

The old truck plow I'm going to weld up to a SSQA plate has two single acting cylinders - one on each side of the A-frame.

Option 1) For a fully manual - and virtually free solution - I'm wondering if I can simply connect the two hoses together on the two single action cylinders? Pushing the blade one way would dump fluid from one cylinder to the other cylinder. Uncoupling the two hoses would then lock the blade in that position as the fluid has nowhere to go. Am I crazy - or would this work?

Option 2) Steal the curl function of the bucket to control the blade angle. Not ideal, but if I get the blade set right and then disconnect the curl (and cap it off) - it shouldn't move again for the rest of the winter (right?). If I tap into the lines before it splits to the left and right cylinders for the bucket - do I then simply connect one line to each of the single acting cylinders on the plow? Someone suggested I would first need to run the lines through a crossover relief valve. Thoughts?

Option 3) My tractor has power-beyond on the joystick controller for the loader. I could tack on an additional open center DCV and run a new set of lines to the plow. Similar question to the option above on the crossover relief valve.

I'm favoring option 1 for this year (if it works), and then option 3 for next year when I have more time (and cash!).

Sean.

I know it's likely been covered many times before - but I'm clearly searching for the wrong terms... I'm looking for information on hooking up snow plow hydraulics (single action cylinders) to the front of my tractor. I've got three scenarios I'm considering from cheapest and most manual, to most expensive and most convenient. Not sure if I've got this right, so any information would be appreciated.

The old truck plow I'm going to weld up to a SSQA plate has two single acting cylinders - one on each side of the A-frame.

Option 1) For a fully manual - and virtually free solution - I'm wondering if I can simply connect the two hoses together on the two single action cylinders? Pushing the blade one way would dump fluid from one cylinder to the other cylinder. Uncoupling the two hoses would then lock the blade in that position as the fluid has nowhere to go. Am I crazy - or would this work?

Option 2) Steal the curl function of the bucket to control the blade angle. Not ideal, but if I get the blade set right and then disconnect the curl (and cap it off) - it shouldn't move again for the rest of the winter (right?). If I tap into the lines before it splits to the left and right cylinders for the bucket - do I then simply connect one line to each of the single acting cylinders on the plow? Someone suggested I would first need to run the lines through a crossover relief valve. Thoughts?

Option 3) My tractor has power-beyond on the joystick controller for the loader. I could tack on an additional open center DCV and run a new set of lines to the plow. Similar question to the option above on the crossover relief valve.

I'm favoring option 1 for this year (if it works), and then option 3 for next year when I have more time (and cash!).

Sean.