Over the last couple days I have done the following:

1-Drained the hydraulic oil.

2-Popped off the top cover on the trans and taken some pics.

Right side of tractor - Forward gear engaged

Right side of tractor - Neutral engaged

Right side of tractor - Reverse gear engaged

Left side of tractor - Forward gear engaged

Left side of tractor - Neutral engaged

Left side of tractor - Reverse gear engaged

Left side of the tractor - Gears 1-4

Left side of tractor - Ranges 1-3

3-Removed the ball detent for review

Ball detent mechanism & paper towel used to wipe magnet off

The ball is in pristine shape, no wear in the chrome.

4- I fished in the bottom of the sump fwd/rev section with a magnet.

I did not find any metal shavings. Just a little gunk shown on the paper towel above.

5-Cleaned the suction strainer

Top of the suction strainer

Bottom of the suction strainer

This could potentially be cause for concern BUT this strainer has never been removed for cleaning ever. A lot of the shavings were long and curled which to me would indicate that they were from the initial manufacture. On the other hand a lot were just metal filings. Note: I don't see any wear other than very light wear on gears etc. anywhere in the transmission.

Crud I got off the strainer

The strainer after cleaning it off with brake cleaner and before I re-installed it.

6-I have replaced the hydraulic oil filter

In the near future I am planning on doing the following:

A-Refill the sump with New Holland fluid.

Question, when I went to the dealer they gave me MAT 3540 fluid. My book says to use NH 134D Fluid. The bucket says that it is a replacement for Multi G 134. Does anyone know if Multi G 134 was a replacement for NH 134D? I'll probably be calling the dealer on this. I don't want to put anything in there but the "perfect" fluid to rule that out.

B-Re-install cover plate and seat

C-Run it for a couple hours to get it up to temp.

If the issue goes away I will chalk it up to the fluid, the strainer, or the hydraulic filter.

If the issue remains I will:

I-Park the tractor and turn it off to see if the clutch may be causing the issue. Theory here would be that the clutch or throwout bearing or whatever does not totally disengage when warm. This would allow me to take it out of gear but not put it back in when the motor is running, which is what I'm experiencing. So in theory if this is the problem then immediately after I shut the tractor off I should be able to shift it from fwd to rev.

II-Take the seat and cover off of the tractor and take the temperature of the fluid in the transmission

III-Check to see what moves and what doesn't. Check the linkages, the fork, the ball detent. If I can't see anything due to the fluid being in the tractor I will drain it.

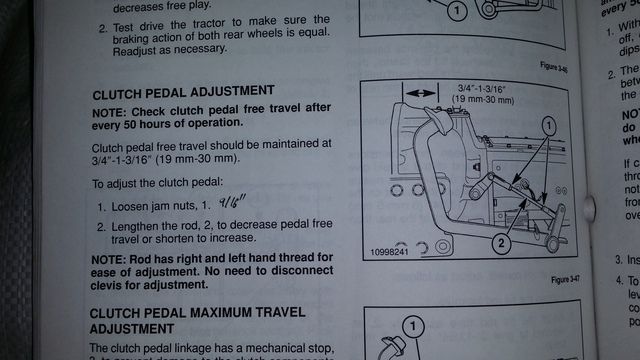

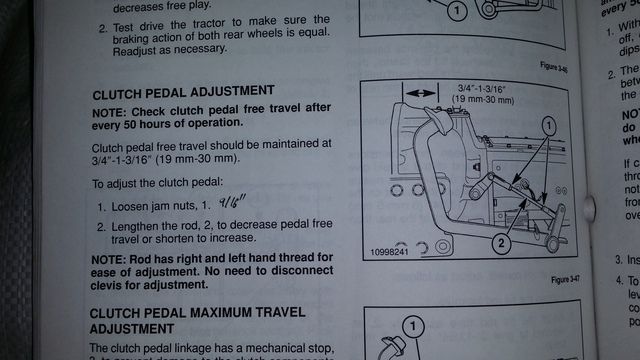

IV-Last thing would be to measure the clutch pedal free play when hot and potentially adjust it to where it was before the 1000 service. As part of this service I did adjust the clutch pedal free play. It was getting to the point where I needed to have my foot firmly to the floor when clutching and it would engage pretty quickly after releasing the clutch. By adjusting the free play, which is now in the middle of the spec, I should be alleviating any problem with the clutch staying engaged but it is something that I did change at that service and it needs to be looked into.

Manual

Current pic showing how far the pedal returnes after hitting tension

Anything I'm missing? I'm hoping to get the fluid grade figured out tomorrow and maybe do my testing Wednesday or Thursday after work.