Thanks Shona13. That's funny, the last time I heard the antirust oil leak thing, it was by a Land Rover guy...

I'm just back from checking how the marks align and according to what you said the pump drive gear would be one full tooth off. With the 24 degrees mark aligned in the oval hole under the rubber plug on the engine adapter plate, the squared end of the circlip comes near the A mark in the pump and I can see the B mark a bit farther at the bottom inside the pump. If I get it right, it wmust mean that the engine as it is now was running with crazy static advance but that's good news since I may just get along by unscrewing the gear and trying to mesh it back on the right tooth. If somebody has been able to put it wrong with the timing cover installed, I may be able to undo the gear and put it back right... I hope...

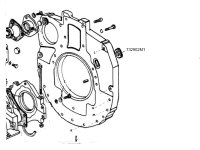

Here are some pics in case it helps somebody someday. I have to say I had a badluck that turned to be a luck. The starter broke (too) so I checked the flywheel marks in the starter hole so I see better. I would have never found the marks looking in the timing hole because its location is so unconvenient... Here are the said marks:

Here is the timing hole hidden under a fuel filter... Good idea... I marked the 24 degrees mark with paint and it's the only way to see it.

So this weekend when it's bright outside I'll try to put the timing back on the right tooth and reinstall the refyrbished starter and see if there is a difference in the engine's behaviour...

I'm just back from checking how the marks align and according to what you said the pump drive gear would be one full tooth off. With the 24 degrees mark aligned in the oval hole under the rubber plug on the engine adapter plate, the squared end of the circlip comes near the A mark in the pump and I can see the B mark a bit farther at the bottom inside the pump. If I get it right, it wmust mean that the engine as it is now was running with crazy static advance but that's good news since I may just get along by unscrewing the gear and trying to mesh it back on the right tooth. If somebody has been able to put it wrong with the timing cover installed, I may be able to undo the gear and put it back right... I hope...

Here are some pics in case it helps somebody someday. I have to say I had a badluck that turned to be a luck. The starter broke (too) so I checked the flywheel marks in the starter hole so I see better. I would have never found the marks looking in the timing hole because its location is so unconvenient... Here are the said marks:

Here is the timing hole hidden under a fuel filter... Good idea... I marked the 24 degrees mark with paint and it's the only way to see it.

So this weekend when it's bright outside I'll try to put the timing back on the right tooth and reinstall the refyrbished starter and see if there is a difference in the engine's behaviour...