excelagator

Gold Member

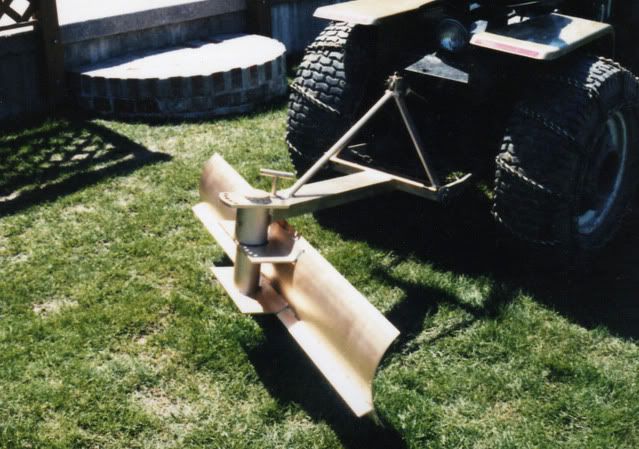

I have some area to smooth out in the near future. I have been thinking about building a 5 or 6 ft back blade for smoothing and buying a 4 ft box blade. Just wondering if anyone has input on this and or photos of your creations? The one area I am lost is the pivot point for angling a back blade.

Dan

Dan