D

Deleted member 371759

Guest

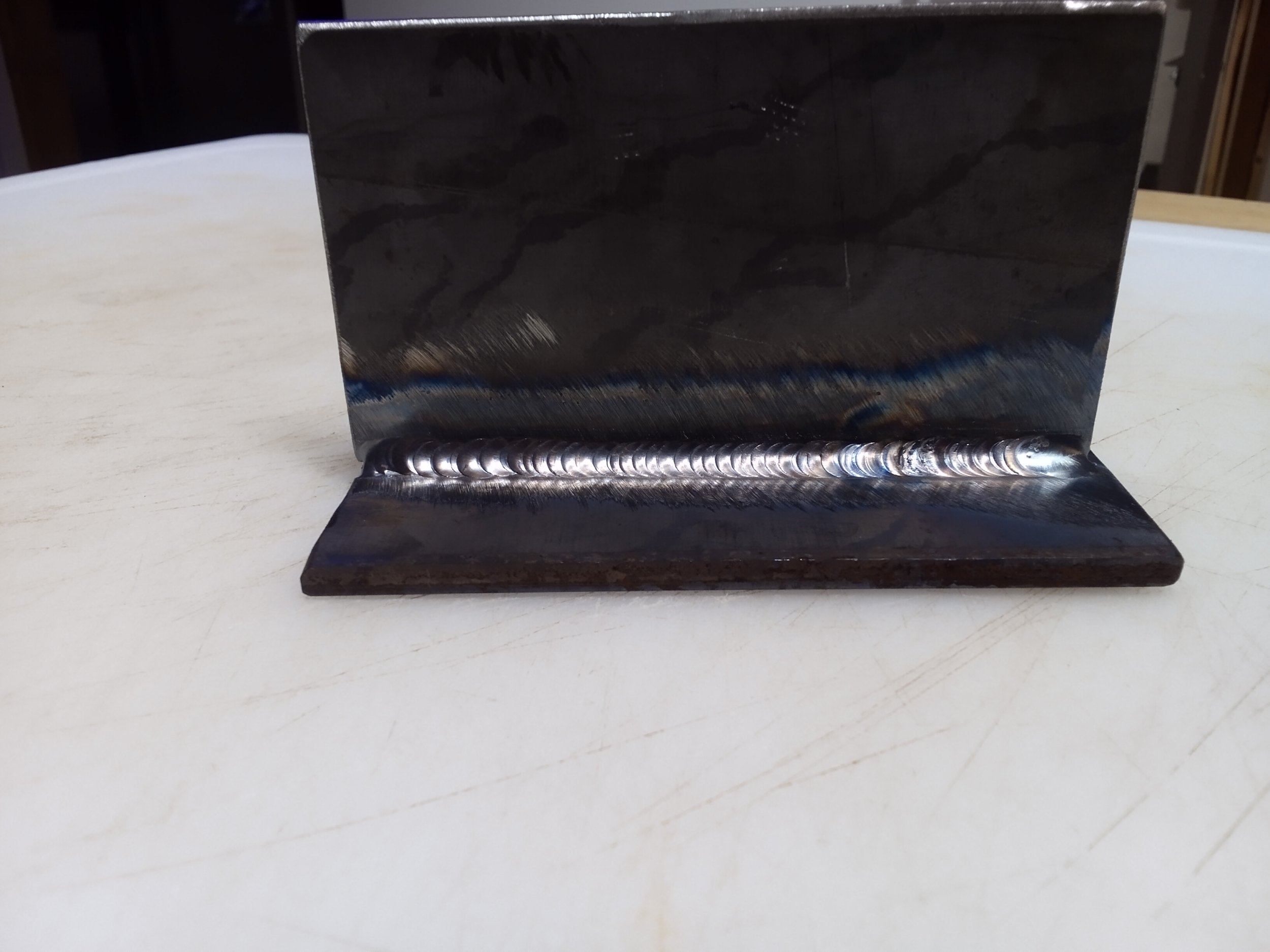

Some TIG welding practice. Feel free to tell me how terrible I am. 3/32 2% lanthanated tungsten, 160 amps. 11/64th hot rolled steel . 15cfh argon. Stubby #8 gas lens.

I may have taken the filler out of the argon shielding.A little ruff at the beginning, very good in the middle (steady and constant) but then there is some porosity at the end... I am sure you know what you did wrong at the beginning but do you know what went wrong at the end ?

You are doing good, keep it up and do more of what you did in the middle.

If I was you I would just get rid of that TIG machine. Send it to me. I could always use another. Take up needlepoint instead. Even better, keep TIG welding because your weld looks fine and your welds will only get better. I know, you will get a lot of nit-picking advice, which is fine, but your weld bead really looks better than many of the beads I see done by folks who weld for a living. There is a little difference in travel speed and it looks like the shielding gas may have been blown away in one spot, but that could just be the camera. I'm pretty sure you know already where the weld bead is not ideal and don't need anybody here to tell you. But to reiterate you bead is pretty good and if you did that bead for me and I was paying for the work I wouldn't complain.Some TIG welding practice. Feel free to tell me how terrible I am. 3/32 2% lanthanated tungsten, 160 amps. 11/64th hot rolled steel . 15cfh argon. Stubby #8 gas lens. View attachment 809108

Thanks. I really appreciate that. Im trying hard to get good at tig welding. I does not come naturally to me. Im not a super coordinated guy. So its going to be interesting. Im also not super artistic which it seems like a lot of good tig welders are.If I was you I would just get rid of that TIG machine. Send it to me. I could always use another. Take up needlepoint instead. Even better, keep TIG welding because your weld looks fine and your welds will only get better. I know, you will get a lot of nit-picking advice, which is fine, but your weld bead really looks better than many of the beads I see done by folks who weld for a living. There is a little difference in travel speed and it looks like the shielding gas may have been blown away in one spot, but that could just be the camera. I'm pretty sure you know already where the weld bead is not ideal and don't need anybody here to tell you. But to reiterate you bead is pretty good and if you did that bead for me and I was paying for the work I wouldn't complain.

Eric