I've got a JD 1026r that I want to either put a tooth bar on or install some weld-on teeth with replaceable tips. Is there any advantage to the toothbar besides being removable? I can't imagine i'd ever want to remove my weld-on teeth. Is there a big difference structurally?

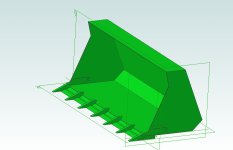

I was looking at these teeth: WET-1 Berlon: Weld on Teeth

I was looking at these teeth: WET-1 Berlon: Weld on Teeth