Honestly, it seems that you are attempting to make rather simple things more difficult than they need to be. Maybe that's just me not interpreting your threads properly.

Ha. Don't worry, no offense taken, it would not be the first time. Realistically I do enjoy just learning about all the things ... Your help here is phenomenal, thanks for what you do for the community. In this case specifically what I want is to have float for both my top (for leveling ground with my rake & blade

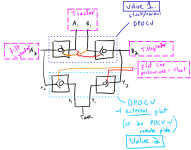

with wheels) & side (for most of the stuff I use on the 3point). And I am not exactly a skilled operator, so I believe maximum travel for both will help me. And I don't want to give up important things like the DPOCV, because that would just make life harder. So I hope to at least understand what all my options are. Also, at this point I"m pushing to get all this onto the top&side links directly so I don't need to futz with modifying any of my implements.

Realistically, if I could afford or justify another 50k in controls, these problems are all better solved with servos & closed loop control ... but alas here we are

Maybe by the time I'm giving my equipment to my kids the hobby-level industry will be there. In the meantime, hydraulics seem fun.

For float, I believe I for a reasonable cost I can cleanly & easily get

small POCV's either tee'd off the existing banjo fittings on-cylinder (or just tucked away up in the tractor), implementing the circuit in my OP. No one seems to do this, but enough folks want float I'm surprised to have not found anyone trying. I will try. Hopefully not fail

, i do have some acreage I have to level (yesterday so to speak)

The picture below shows where the slot float feature is on a side link. This feature takes a rectangular head pin that either has the pin locked down at the bottom location or is turned vertical to allow the draft arm to float up-down.

Makes more sense you were talking side link. That's a clean & elegant solution to get a small amount of side-to-side float. Is it enough? I don't know. You're skilled & popular enough you're booked out pretty far - so due to insufficient planning I'm going to spend a bit more, and invest a bunch of time, trying to get the full range

At least it will give me something worthwhile to use the machineshop for!