maxxum5140

New member

- Joined

- Nov 8, 2013

- Messages

- 2

- Location

- orkney

- Tractor

- mccormick xtx 200, xtx 185, case 5140, 956xl, 1056xl, ford 6610, david brown 1390, mf 135, case cx330 and 130 excavators

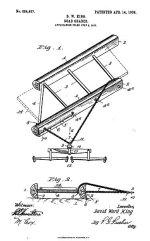

Hello i am hoping to build a tractor pulled grader much like this one Landoll Corporation Icon Industries I have never seen one of these machines here in the UK, no one seems to build them here so im going to have do do it myself. I have seen them in the US and Australia a few years ago when i worked on combine crews ( i should have wrote down some dimensions back then!). I was hoping someone here has built or owns a similar machine and could give me a hand with the measurements / ideas.

I'm not sure on what length of blade yet. My largest tractor is 200hp weighing 10.5 tons inc front weights so should pull a fair bit. I would also use the blade to level rough ground after ploughing / harrowing by running at 90 degrees with plates on the ends of the blade to create a sort of box to pull the soil from the high bits into the low bits.

For the blade i plan to use a half of a piece of 3' pipe cut lengths ways with a heavy H beam welded o the back of it and i already have plenty wheels and axles. The rest of the steel and the hydraulics will all have to be bought in. I was thinking an old wreck of an excavator might be a good start - use the slew ring for the blade pivot and the arm for the back bone of the grader and you'd already be more than half way there with the hydraulics, pivot pins and bushes. If i happened to own one it would be fine but the price even for a wreck these days is a lot of money. Might just be better to go out and buy new steel and hydraulic rams?

I'm not sure on what length of blade yet. My largest tractor is 200hp weighing 10.5 tons inc front weights so should pull a fair bit. I would also use the blade to level rough ground after ploughing / harrowing by running at 90 degrees with plates on the ends of the blade to create a sort of box to pull the soil from the high bits into the low bits.

For the blade i plan to use a half of a piece of 3' pipe cut lengths ways with a heavy H beam welded o the back of it and i already have plenty wheels and axles. The rest of the steel and the hydraulics will all have to be bought in. I was thinking an old wreck of an excavator might be a good start - use the slew ring for the blade pivot and the arm for the back bone of the grader and you'd already be more than half way there with the hydraulics, pivot pins and bushes. If i happened to own one it would be fine but the price even for a wreck these days is a lot of money. Might just be better to go out and buy new steel and hydraulic rams?