Ray were you referring to running a separate ground wire from each light back to the ground coming from the tow vehicle? While I had not planned on doing that I was going to run a 10 ga wire from the trailer plug to the frame and then ground the lights at common point along the frame. I figured doing it in this manner I would not have to rely on a ground connection between the ball and couple for a ground. I was also thinking about hitting all of the frame ground points with liquid electrical tape to help prevent corrosion/rust.

BTW my soldering skills are worse than my diagramming abilities so I have used crimp+heat shrink connectors with shrink tubing over top on all the connections I have made so far.

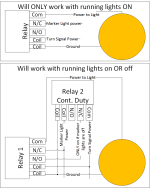

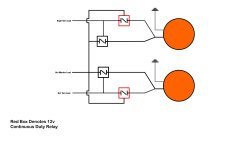

I can't be the first to think of this, but what would happen if I used heavy duty continuous cycle relays to switch between the marker signal and turn signal powering the clearance led? Something like this:

I guessing that with a regular relay the pulsed signal from the turn wire would very quickly burn out the relay controlling the marker wire. Would a continuous cycle relay overcome this issue and provide a useable life cycle? Also, I am guessing there might be a problem with chatter within relay caused by using the turn wire to control the relay but I am not experienced enough to know one way or another? Any thoughts guys?

BTW my soldering skills are worse than my diagramming abilities so I have used crimp+heat shrink connectors with shrink tubing over top on all the connections I have made so far.

I can't be the first to think of this, but what would happen if I used heavy duty continuous cycle relays to switch between the marker signal and turn signal powering the clearance led? Something like this:

I guessing that with a regular relay the pulsed signal from the turn wire would very quickly burn out the relay controlling the marker wire. Would a continuous cycle relay overcome this issue and provide a useable life cycle? Also, I am guessing there might be a problem with chatter within relay caused by using the turn wire to control the relay but I am not experienced enough to know one way or another? Any thoughts guys?