I own a 1964 MF 202 Workbull backhoe. One cylinder on the hoe needs new seals but I can’t get the bearing to tap far enough into the cylinder to remove the retaining clip ( splitting). The oil is drained from the cylinder but it’s like the bearing is hitting up against something when I use a brass punch and hammer to try and move the bearing into the cylinder further. It did move some but not far enough. Any ideas folks? Thanks, Gord

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More options

Who Replied?

/ Trouble with Cylinder Disassembly

#1

tshep

Gold Member

Oil line fitting?

Thanks for your reply tshep. It could be the oil fitting line but the problem is the fitting is welded in place when the cylinder was built so how would they assemble it? I was thinking that maybe the retaining ring itself is preventing the bearing from pushing in further? Other then using shim stock around the retaining ring to try and compress the split retaining ring and get it to come out past the threads I’m not sure how to get the retaining ring out. But I’m not sure if there is enough room to bring it past the threads? Maybe the bearing and ring have to come out together once the retaining ring is compressed with shim stock? I would have to imagine other people have run into this problem but I can’t find their solution.

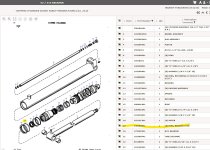

Attachments

Is it possible there was a set screw in the side of the cylinder that either got the head broke off or is recessed and you haven't seen it? I've seen cylinders that have a set screw that goes into the gland nut, so you can't loosen the nut until you get that screw out.

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 3,020

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

K5lwq

Elite Member

- Joined

- Aug 6, 2017

- Messages

- 4,918

- Location

- Mineola, TX

- Tractor

- Kioti LK2554, Branson 4815C, Satoh Beaver, Speedex

If it moved in some then you should be able to remove the ring. This is not a typical snap ring you use snap ring pliers on. You need a couple really good picks.

Start at the end of the ring and work a pick in behind the ring and pull it out of the grove. Then while holding it out work another pick in so you can start working it out. After you get a few inches out of the grove it will come the rest of the way pretty easy.

Then use the cylinder rod as a slide hammer to drive out the gland seal.

Start at the end of the ring and work a pick in behind the ring and pull it out of the grove. Then while holding it out work another pick in so you can start working it out. After you get a few inches out of the grove it will come the rest of the way pretty easy.

Then use the cylinder rod as a slide hammer to drive out the gland seal.

LD1

Epic Contributor

For reference, its called a gland and not a bearing.

Now, is the gland driven into the piston? It looks like you have the cylinder rod extended almost all the way....and supporting by it. That could be causing you issues. Try driving the rod in a little first.

Now, is the gland driven into the piston? It looks like you have the cylinder rod extended almost all the way....and supporting by it. That could be causing you issues. Try driving the rod in a little first.

ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Yeah, I'd want the rod mostly collapsed so it would minimize the rod applying binding pressures on the gland.For reference, its called a gland and not a bearing.

Now, is the gland driven into the piston? It looks like you have the cylinder rod extended almost all the way....and supporting by it. That could be causing you issues. Try driving the rod in a little first.

wdchyd

Elite Member

Just now seeing this…….bring the rod all the way out, then tap the gland (and the piston will follow) in about 1-1.25”…… you’ll see a around retainer in the groove, take it out…….then slam the whole rod assy out using a chunk of steel stock in the rod eye.