Thanks for all the great information in this thread. I have a Scotts by manufactured by John Deere L2048 with a Tuff Torq K46AC used only for mowing, some hilling, some relatively flat. I typically put a little over 100 hrs. a year on it. Followed the operators manual instructions as far as service to transmission (if it is not broke do not fix it) until last June when it refused to climb a hill after the oil had warmed up with my 270 lbs. on it. At that point took the transmission off dump the oil out (it looked pretty bad) and replaced it with Castrol 5W-50 synthetic as per the Tuff Torq web site recommendation. I managed to limp through the rest of the mowing season mowing the hills before it warmed up and then one hill climb at a time. By end of the season, with 1035 hours of service on the machine, it would not pull a slight incline and had to be opened up.

Has anybody notice aluminum material sticking in the threads of the lower case bolts?

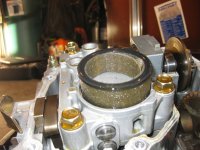

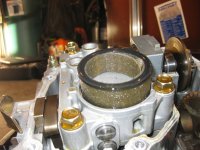

The inner liner of the filter is pulling away, has this been found before?

Most of the grit in the lower case was found in the shallow end of the gear side of the unit.

The magnet was fairly covered with filings.

I did not find anything wrong with the gears.

I do not remember anybody in this thread mentioning dimples on the plate/washer on the thrust bearing that the pistons in the motor ride against, Number 37 on the Tuff Torq schematic, the one in the wedge that frequently gets installed backwards.

They are so uniform that I cannot believe that this is due to wear, it looks too manufactured.

Does anyone know if this is normal or should it be replaced? I assume the problem is on the hydraulic side, but do not have any micrometers to measure the clearance of the pistons in the pump and motor. The pistons feel pretty tight, but without any comparison I am not sure I can tell the difference between .001 inch clearance and five times that amount or .005 inch clearance. There are wear marks on the surfaces of the Center Case that the pump and motor rotate against, but I cannot feel them with my finger.

The main question is should I try to polish the Center Case with the sandpaper method described by others in this thread or spend the big bucks on a new one as recommended by Tuff Torq?

The main question is should I try to polish the Center Case with the sandpaper method described by others in this thread or spend the big bucks on a new one as recommended by Tuff Torq? I wonder if they harden the surface in the manufacturing process, therefore the sandpaper polish may remove all harden material leaving behind only soft aluminum to wear grooves rapidly. The last big question is about lubrication. I am wondering if the broad range of viscosity (5W-50) recommended is to accommodate all uses, in all seasons worldwide, when I want to use the best for me operating in Central Kentucky from April to November (never with an ambient temperature below 50 F). If the loss of torque is due to thin oil leaking by worn mating surfaces, I would like to use as thick of oil as possible that will not allow excessive wear to the mating surfaces during warm up. I will appreciate any knowledgeable input.