The outside 2" cylinders are too wide to fit into the loader frame. You might have noticed that I welded on extensions that were small enough to fit. I mention it somewhere in the videos.

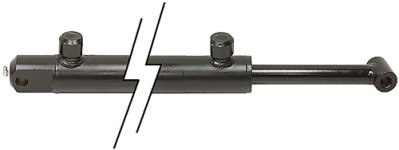

The cylinders I found have a tang base end. From the picture I believe I should be able to simply weld on the cross-tube to the end with the hydraulic fitting at the 3 o'clock position (towards the hood of the tractor). If the tang end is too wide it should be amendable to trim a little.