REF.: Part # 23075 30 inch Rotary Mower Deck Lubrication question:

REF.: Part # 23075 30 inch Rotary Mower Deck Lubrication question:The Manual, FORM NO. 37063 (7-86) States that Multi-Purpose Grease should be added until it "shows at the Mower Shaft--Under the Mower Deck.

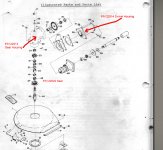

Applying grease through The Grease fitting, P/N 271434, simply deposits the grease into the P/N 22513 Gear Housing, & on to the P/N 22518 bevel gear, without pressure.

In order for grease to be forced down to be seen at the P/N 22522 Seal below the Mower Deck, the entire P/N 22513 Gear Housing, & P/N 22514 Swivel Casting would have to be completely packed with grease, & the grease forced under pressure past the Bevel Gear, Pinion Gear, upper & lower bearings & races before it could be forced past the P/N 22522 Seal, to be "seen at the bottom".

QUESTION: Is the entire P/N 22513 Gear Housing, & 22514 Swivel Casting meant to be entirely pre-packed with grease?