First off, let me preface this by saying that I am not picking on Miller. I have a Lincoln & the recommended settings in the book & what the welder it's self recommend are similar to what the manual for the Miller. Miller just happens to have a online calculator that I can use for comparison.

So, my question is about comparing what is the book setting vs the online Miller Calculator recommend. MIG Flux-Cored Weld Setting Calculator

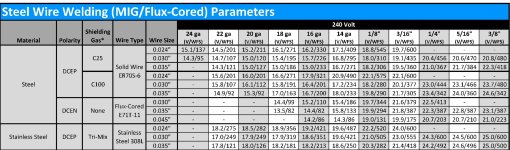

Let's compare the settings for 1/8" metal & using .035" wire. No shielding gas. Here is part of a screen shot from the pdf manual.

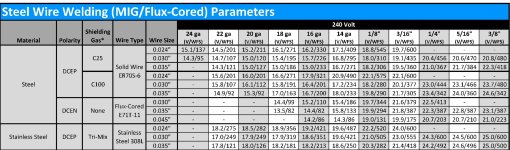

Here is a screen shot from the online calculator.

I have a lot better luck with the settings from the calculator. Why is there such a difference?

So, my question is about comparing what is the book setting vs the online Miller Calculator recommend. MIG Flux-Cored Weld Setting Calculator

Let's compare the settings for 1/8" metal & using .035" wire. No shielding gas. Here is part of a screen shot from the pdf manual.

Here is a screen shot from the online calculator.

I have a lot better luck with the settings from the calculator. Why is there such a difference?

Last edited: