Btw. Checked on your pedal. Seems someone forgot to pack it in the box in the rush of the big shipment arriving and 200 units going out a day. Looks like our shipping department is being pushed to the max with the new model units, but It's on the way now.

Thanks Mark. Never had a concern.

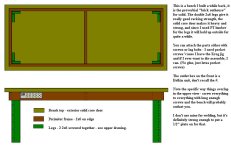

I've got to get some kind of a cart for it and a place to keep the rods and little stuff out of harm's way.

Then I'm going to get a buddy of mine to come over and we are going to walk through each part together and put the unit together.

and take it outside to mutilate some scrap steel. Been waiting to do this a long time. Welding in front of a suburban tract home should really bring the local kids in. Hey Mister, watcha doin'? or perhaps, waaaazzzupppppp. No, not our neighborhood...

And under the close eye of my wife, who will likely "supervise" from a second floor window above, I will try to produce enough

sparks smoke and excitement to satisfy all in attendance. I really will try to make the first weld properly though. Angle, depth, amps, etc

And maybe I'll take a picture of it for your inspection. The slag will just disappear, the puddle will flow with even precision the entire length and

after cooling, the surface will be so smooth I can see my face in the weld. Well, a man can only dream...:dance1:

Then haul it over to the farm and set it up properly on top of heavy gravel.

Do mice like to eat these things? Open shed... never thought about that.

Though I always have to check the various motors for nests in the beginning of the season.

Mafia mice, maybe I should pay them their vig in birdseed, on the other side of the shed...

where's a feral cat when one needs them?