Glenn,

I've been struggling over this too for my 2910. It's compounded by the fact that I've got what seems to be a much larger control valve assembly than at least birds, which seems to be about half the size of mine.

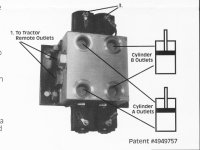

Right now I'm leaning towards mounting it with the valve assemble standing upright positioned between the seat and ROPS bar on the right side of the tractor. It will involve moving the flasher light tothe outboard side of the ROPS, but there's a bracket to do that. The control levers attach to the top of the valve assemble and will point forward. Moving them up/down will control cyl movement. The 4 outlets from the valve assembly face the rear of the tractor, which is like because I can attach disconnects directly to the valve body and plug/unplug hoses right at the rear of the tractor where I want them. Before I was having trouble finding a clean way to mount the valve assemble, mount a set of 4 disconnects, and route hoses between them. The issue of physical protection of the hoses and levers is not one I had considered but I think this placement will help somewhat with that problem.

When I first started planning this I also considered the remote electric valves and the selector switch approach that allows the loader control to double as a TnT control. You've got me reconsidering these now, but let me recount the reasons why I passed on them earlier. Maybe it will help me figure out if I'm still doing the right thing.

The electrical controlled valves are clearly very attractive because you can separate the bulky valve from the control. I passed on them for two reasons. If I've misinterpreted how they work hopefully someone who's used them or researched them more thououghly can correct me, but it looked to me like they were binary on/off controls. A manual valve has a range of operating positions and at least on my loader I use that extensively for fine adjustmements and positioning, and it seemed to me that fine adjustment was probably even more important on the TnT. I did see Ron mention that flow restrictors are available so the valves don't produce a gusher when activated, but I still think the variable control will be important. Maybe some TnT users can comment on how important this really is.

The second reason I passed was cost. It's been hard justifying the cost of a TnT and the electric valves are 2x the cost of a manual valve.

The other approach that I was originally leaning towards was a set of selector valves that would channel the loader valve ports either to the loader or to my rear couplers & TnT. When the selector is in one position the control operates the loader as we all know and love, and in the other position the control would operate the TnT. This was very attractive to me because it eliminated a valve for which I couldn't find a mounting position (right back to the original problem), I could place the selector valves somewhere on the loader frame where there's room, not have to tap into the rear hydraulic port of the tractor, etc.

But then I ran into trouble finding the right selector valve. Northern Nydraulics has one but it would only control one of the two circuits for the loader so I woudl need two. Then there would have been two selector levers, not one, so some of the simplicity was wearing thin. I looked at the electric controls, ignoring cost for a second, and they are not selectors, they are control valves so I'd need two of them.

I then realized that I could get most of the same benefits by mounting a second control valve just below the loader joy stick, still tap into the loader hydraulic supply, and be able to operate the TnT and loader independently. This seemed great and was the "final" plan, until I posted it here and everyone said I was making a mistake placing the TnT control up by the loader control and that it really needed to be somewhere around the fender. After a few "make-believe" sessions of my tractor trying to imagine how Box scraping and snow blowing would work, I saw the wisdom in the advise I was given.

I'd be real interested to hear from people using the electric controlled valves to understand how precisely then can be controlled. By guess is that you need to pulse the switch to make fine adjustments to the TnT position. Does this work OK or is it a nusance.