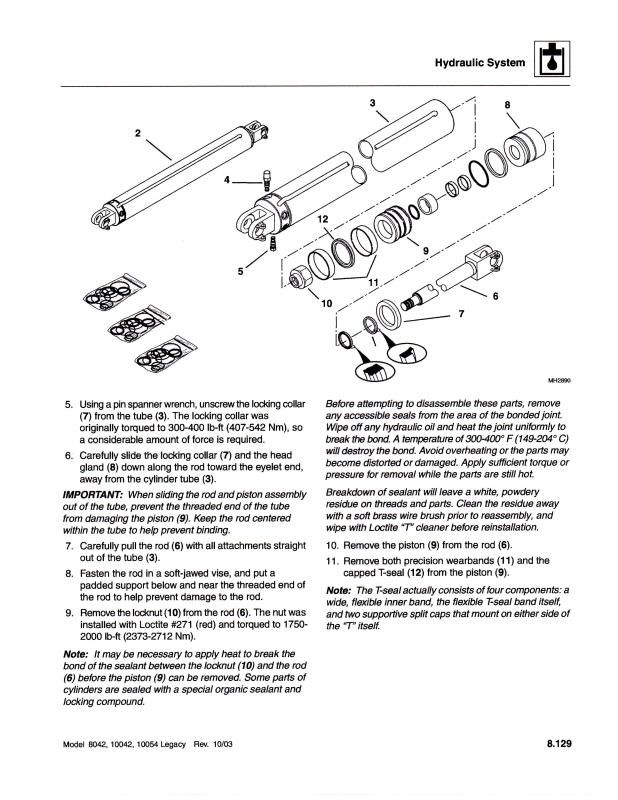

Well that's where I differ from you.....I see it all the time.....new tractor cylinders are not engineered the same as these pics you show of manlifts, cranes, and quality construction equipment......not the same internally.......

Just open up a Bobcat cyl and look at the piston seal.....it's .125 wide....They are a great machine but there cyls have always been chinsy....

You misunderstood my post. I said that the cylinders on the machines I used as examples are far better than your typical run-of-the-mill cylinders. I realize that it may have gotten confusing when I mentioned that the manlifts aren't required to have rapid cycle times like the telehandlers, but all of the cylinders used for any load lifting/positioning/holding applications on both types of machinery are high-dollar units with holding valves/load checks built into the cylinders.

How "high dollar" are they? Well, as an example, the fork tilt cylinder circled in blue in this photo of the telehandler costs us about $1600....and that's dealer cost. We've had them damaged before and the customer gets upset when they get a bill because they "can buy a cylinder that size for $200 over at Fleet Farm or TSC...."

(and they "know that" because that's what the FEL bucket curl cylinder for their tractor at the farm cost them...)

:laughing: