Hello - new to this forum. I have a Yanmar 1700. It ran pretty well for 20 years, then stopped starting. Over the last few years I've slowly replaced many parts - injectors, injection pump, head (old one was leaking water into the cylinders), pistons, sleeves. With many attempts I can get the tractor to start and it runs but has little power. I checked compression and have 600 psi and 550 psi readings for the two cylinders.

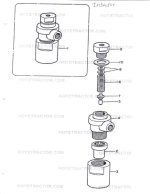

I took the injectors out to do the compression tests and noticed the injector insulators seemed 'burnt '. Also the holes in the injector cavity nozzles have been enlarged quite a bit. Please see the photos.

Any thoughts on what is causing these results or what to do with replacements to avoid this? These parts have had only an hour or so of run time on them (new parts from the rebuild and only 4 or 5 10-15 minute runs).

I'm wondering if part of the problem is injection timing being off or perhaps combustion happening inside the nozzle as well as in the cylinder?

Thanks for any thoughts on this.

I took the injectors out to do the compression tests and noticed the injector insulators seemed 'burnt '. Also the holes in the injector cavity nozzles have been enlarged quite a bit. Please see the photos.

Any thoughts on what is causing these results or what to do with replacements to avoid this? These parts have had only an hour or so of run time on them (new parts from the rebuild and only 4 or 5 10-15 minute runs).

I'm wondering if part of the problem is injection timing being off or perhaps combustion happening inside the nozzle as well as in the cylinder?

Thanks for any thoughts on this.