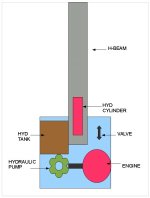

Alright, I bought and received one of these from the guy in Georgia off of ebay. $575 including shipping, great packaging. I put 15w40 in it and am running it about 2 hours each night on low idle to help break it in.

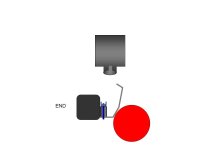

Anyway, for anyone who knows a little about mufflers and diesels, see if you can help me out. I'm trying to position it on my log splitter so that i can access the fuel tank easy, the pull start, the oil drain, etc. The only problem is that my muffler is close to the cylinder and the exhaust outlet points at the cylinder. These pictures show the heat shield removed. I dont have a wire welder, only a stick so i dont think i can weld a new port in this thing. And on top of that, the two halves are crimped together so i can't see what the inside looks like.

I thought about just putting a 90 degree piece of pipe or conduit on the outlet and bring it out the back or upwards, but it would look cleaner if i patched the existing outlet and made a new one facing the back of the splitter/recoil side of the engine. What do you all think?

Anyway, for anyone who knows a little about mufflers and diesels, see if you can help me out. I'm trying to position it on my log splitter so that i can access the fuel tank easy, the pull start, the oil drain, etc. The only problem is that my muffler is close to the cylinder and the exhaust outlet points at the cylinder. These pictures show the heat shield removed. I dont have a wire welder, only a stick so i dont think i can weld a new port in this thing. And on top of that, the two halves are crimped together so i can't see what the inside looks like.

I thought about just putting a 90 degree piece of pipe or conduit on the outlet and bring it out the back or upwards, but it would look cleaner if i patched the existing outlet and made a new one facing the back of the splitter/recoil side of the engine. What do you all think?