rus_geek

Gold Member

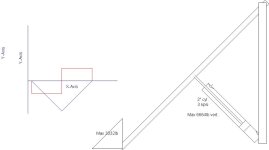

Here's my vague understanding, based on trying to do beam calculations for trailer frames. Looking at a VERY simplified loader design, the red graph represents the forces acting on the loader arm, while the blue line represents the stress. (Anyone with more engineering than my paper napkin doodles should feel free to correct my terminology). The most stress in the member is at the point the cylinder contacts the arm. This is the point where the most strength is required. To either side of that, the arm can be tapered, due to the lower stress levels.

In the example of running into immovable objects (hitting a rock while plowing snow, for example), additional forces in the horizontal plane come into play.

-rus-

In the example of running into immovable objects (hitting a rock while plowing snow, for example), additional forces in the horizontal plane come into play.

-rus-