OK, guys. I said it once before...I'm not a fan of speculation.

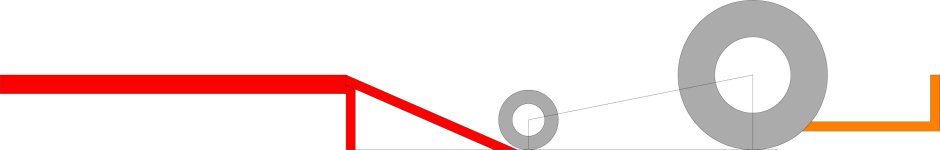

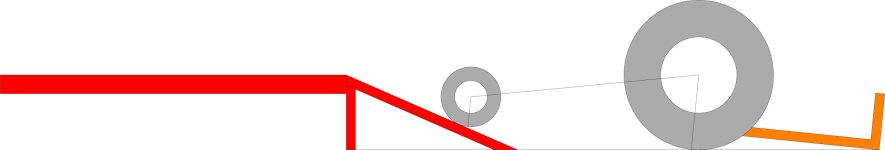

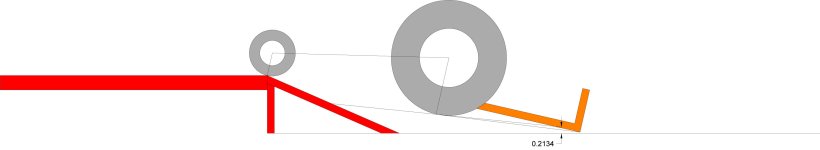

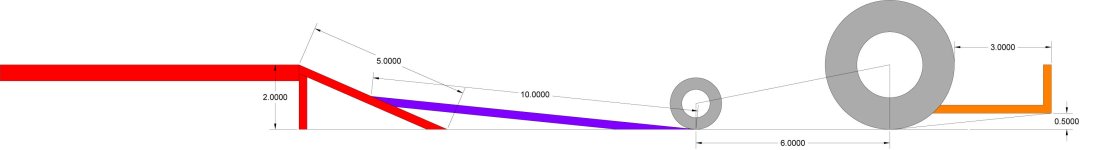

So I built a simple replica of the situation in AutoCAD to demonstrate the problem and a couple different solutions.

I used fairly conservative parameters based on the OPs input and information available online. I put the deck 24" off the ground (Hudson says 23"). I assumed stock ramps are 5' long. The wheelbase of his tractor is 71", but I put in 72" (even 6 foot). I made the rear-most tip of his backhoe 3 feet behind the rear-most point of his rear tire and put that corner a mere 6" off the ground.

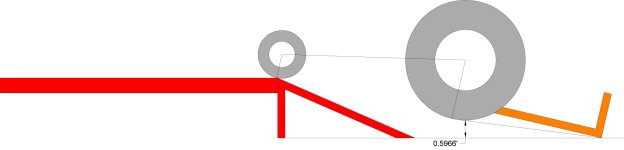

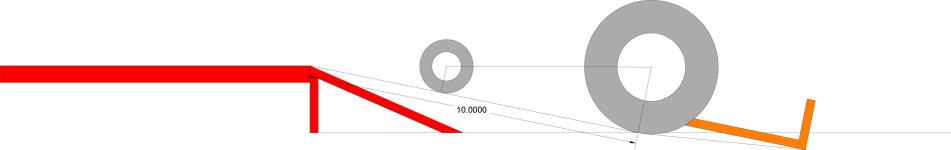

From my model, you can see that even if the stock ramps were extended to 10 feet long (which I wouldn't want to lift or have sticking up during transport), it wouldn't come close to working. I don't even think 12 foot long ramps would work IF they are hinged at the trailer deck.

He needs "sub-ramps".

By my calculation, sub-ramps that are 10' long (properly positioned) or 8' long with a "ledge" at the lower end at least 3 inches tall will allow the point of the backhoe to swing harmlessly in the air as the tractor is loaded.

As I stated before, I have the identical problem, albeit on a smaller scale with my little BX tractor/backhoe, and this is how I solved it. But my sub-ramps are only 8 feet long and could be a little shorter.

I hope everyone finds this information helpful to the discussion.

Even more, I hope the OP tries it with a few 2 x 12s and tells us that it works!!!