radioman

Super Member

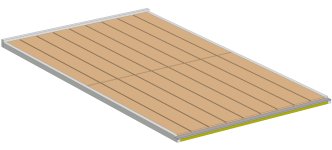

Another way is to get pressure treated 2X6's and run it in the table saw to make a groove wide enough for the 1/2 pressure treated plywood. miter the corners. glue the insides of groove with water resistant glue and Use a rubber mallet to persuade the 2X6's onto the plywood. use screws to hold the plywood in the groove all the way around. Use cut up scrap plywood to cover the corners to give it strength and screw them on the inside of the door.

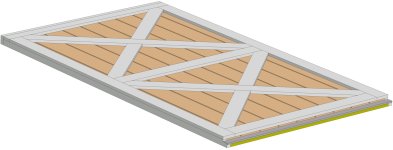

This is what I did for my fathers shed that I rebuilt for him. The doors are a full 4X8 sheet,two doors each on hinges. The only regret we have with this door is that we made it a swinging door and its a pain in the winter since the doors swings out. The snow HAVE to be shoveled first before opening the door. We ended up building a little roof over the door area so we dont have to shovel it. The wood we used wasn't pressure treated but the doors are still standing today from 20 years ago and no rot yet.

This is what I did for my fathers shed that I rebuilt for him. The doors are a full 4X8 sheet,two doors each on hinges. The only regret we have with this door is that we made it a swinging door and its a pain in the winter since the doors swings out. The snow HAVE to be shoveled first before opening the door. We ended up building a little roof over the door area so we dont have to shovel it. The wood we used wasn't pressure treated but the doors are still standing today from 20 years ago and no rot yet.