Jerry/MT

Elite Member

- Joined

- Feb 2, 2008

- Messages

- 3,141

- Location

- North Idaho-The Palouse

- Tractor

- New Holland TD95D, Ford 4610 & Kubota M4500

OK guys,

Not getting many responses lately. I have been welding on the boom portion as of today. I completed the connection to the fork frame, for the main boom section and the two lift points on the boom.

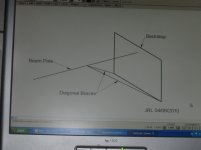

My next big decision is how to brace and support the boom on the forks. I am already venturing away from my sketch.

My question is, should I put the bottom supports all the way back to the bend in the forks, or should I go out about 18 - 24"s? Also how much bracing should I do for lateral movement on the boom? Any input is very much appreciated at this point. I will post pictures of progress later tomorrow.

Mike

If I was going to do this the way you appear to be going, I'd build a fitting around the verical part of the forks that would hold the bottom of your boom structure against the front surface of the fork vertical piece and that could be pinned in place so you can easily remove it. A [ like piece with longer legs that could be drilled a fitted with a pin. I'd do the bottom fitting similarly on the horizontal part of the fork. Then you'd be restrained laterally, vertically, and horizontally.

The pin joint and the angled supports you show on your sketch should provide adequate lateral support to the boom. It's meant to lift not to pull laterally. if you intend to pull laterally with it also, you need to go back to the drawing board. You can stiffen the boom pole to prevent it from bending at that node by welding stiffener peices on the pole in the area where the braces meet the boom.

As I look at your forks, I would have considered making some pin attachments on the edges of the backstop and some pin fittings on the pole. These pin fittings would then take diagonal braces that ran from the pole to the backstop. Then using a pin fitting in the center of the backstop as you all ready plan to do, you 'd have a strong quick attach boom pole for your forks that had a some lateral capability because of the wide "wheel base" of the diagonal braces. It would be light weight and a lot easier to construct than what you are doing now because you'd be using the back stop for structure. Pretty efficient. I don't know what your backstop is made out of so you might have to reinforce it with a full width plate thatthe pin fittings attached to. Hope this makes sense to you.

Last edited: