You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

practicing with my new mig Question ?

- Thread starter Jeff Lary

- Start date

- Views: 5299

/ practicing with my new mig Question ?

#31

kevinj

Veteran Member

- Joined

- Jul 5, 2003

- Messages

- 1,419

- Location

- West MI

- Tractor

- BX-1860, L3940HSTC, B7500, Farmall M, Farmall 560D

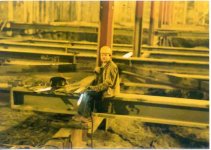

I think these were W14-inch x 311-pound beams. Something like 2 1/4-inch thick flanges.

I'll bet you weld that out "quick a minute":laughing:

Seriously, how long to fit and weld out a joint like that???

Shield Arc

Super Member

how long to fit and weld out a joint like that???

A lot of variables to that question. If at all possible we would try and weld everything flat, (roll it).

It's been so long now I think that job was in 1987. I would guess 5 to 6-hours, if everything went right.

kevinj

Veteran Member

- Joined

- Jul 5, 2003

- Messages

- 1,419

- Location

- West MI

- Tractor

- BX-1860, L3940HSTC, B7500, Farmall M, Farmall 560D

A lot of variables to that question. If at all possible we would try and weld everything flat, (roll it).

It's been so long now I think that job was in 1987. I would guess 5 to 6-hours, if everything went right.

Not as long as I thought it would take, we recently put in some 12" sch 40 steam main and that was about 3 hrs per joint, B31.1 of course.

Shield Arc

Super Member

we recently put in some 12" sch 40 steam main and that was about 3 hrs per joint, B31.1 of course.

What is B31.1?

Did you do that with SMAW or GMAW?

We normally ran 5/64" dia. wire, and sometimes we would have the large LN-7, 8, or 9 wire feeders which will all take 60-pound coils of wire. Then we would go with 3/32" dia. wire. Either 5/64" or 3/32" dia. wire will really lay down the iron with 400 to 500-amps pushing it!

kevinj

Veteran Member

- Joined

- Jul 5, 2003

- Messages

- 1,419

- Location

- West MI

- Tractor

- BX-1860, L3940HSTC, B7500, Farmall M, Farmall 560D

What is B31.1?

Did you do that with SMAW or GMAW?

We normally ran 5/64" dia. wire, and sometimes we would have the large LN-7, 8, or 9 wire feeders which will all take 60-pound coils of wire. Then we would go with 3/32" dia. wire. Either 5/64" or 3/32" dia. wire will really lay down the iron with 400 to 500-amps pushing it!

B31.1 is an ASME pipe welding code. The procedure was for 1/8 6010 open root, 3/32 7018 fill & cap, all uphill.

And I am not a pipe welder but it was my project.

KWentling

Veteran Member

- Joined

- Jun 22, 2002

- Messages

- 1,170

- Location

- Rozet, Wyoming

- Tractor

- Kubota BX22, Kubota ZD21, Kubota M7060

We normally ran 5/64" dia. wire, and sometimes we would have the large LN-7, 8, or 9 wire feeders which will all take 60-pound coils of wire. Then we would go with 3/32" dia. wire. Either 5/64" or 3/32" dia. wire will really lay down the iron with 400 to 500-amps pushing it!

That will separate the men from the boys. We run 1/16" Dual Shield for almost everything at the shop. We tried running a few spools of 5/64". Worked great doing build up in the rotators (have run 3/32" Dual Shield and 1/8" sub arc there too), but that is a challenge running by hand for someone like me (machinist who also welds once in a while). Our GOOD welders could get along OK with it, but it was a handful for me.

Kim

Shield Arc

Super Member

Thanks for the info Kevin, I'm not up on pipe codes, or pipe welding so to speak.B31.1 is an ASME pipe welding code. The procedure was for 1/8 6010 open root, 3/32 7018 fill & cap, all uphill.

And I am not a pipe welder but it was my project.

Kim it's really not that hard. When splicing these beams we would generally use start, and run off tabs. Short piece of angle iron on each side of the flange works great. and a piece of flatbar on the web. When the splice is complete just torch them off and grind flush. With these tabs you can run hot and fast!That will separate the men from the boys. We run 1/16" Dual Shield for almost everything at the shop. We tried running a few spools of 5/64". Worked great doing build up in the rotators (have run 3/32" Dual Shield and 1/8" sub arc there too), but that is a challenge running by hand for someone like me (machinist who also welds once in a while). Our GOOD welders could get along OK with it, but it was a handful for me.

Kim

KWentling

Veteran Member

- Joined

- Jun 22, 2002

- Messages

- 1,170

- Location

- Rozet, Wyoming

- Tractor

- Kubota BX22, Kubota ZD21, Kubota M7060

Thanks for the info Kevin, I'm not up on pipe codes, or pipe welding so to speak.

Kim it's really not that hard. When splicing these beams we would generally use start, and run off tabs. Short piece of angle iron on each side of the flange works great. and a piece of flatbar on the web. When the splice is complete just torch them off and grind flush. With these tabs you can run hot and fast!

I have used run off tabs several times. Then air arc them off. I'm sure a little practice with it would have helped. I just went back to using the 1/16" I was comfortable with.

Kim