J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,973

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

Thanks everyone for your input. I sure wish I could glean all the helpful info in to formulating a hydraulic design. I guess at this point it's honestly over my head. I just don't know enough about hydraulics, there are so many choices and mistakes are too costly.

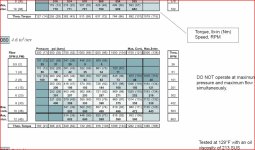

I refuse to give up! I have yet to find anything similar to get earnest ideas off of. Some how I need to drill down on the variables. If I use a high rmp motor, which one? If I go with pto pump, what is the list of components to make that system, and still, which motor? Why is there no impact to the scenario if there is a belt and pulleys to change the rpm's?

The physical build exceeded all my expectations. It was an idea I'm sure everyone has thought about. I expected it to be too heavy to extend so I slapped it together expecting to fail. But its not too heavy at all.

As far as the danger of debris, I designed the adjustments so it never can aim horizontally at me. I also will put a rubber shield on the side facing me and of coarse wear proper fighting gear. :laughing:

Thanks to TBN there's a place to talk it out.

There is impact to the scenario by using belts and pulleys. If you increase the rpm of the blades, the torque goes down.