nealfris

Bronze Member

- Joined

- Aug 16, 2010

- Messages

- 81

- Location

- Marshfield, MA / Arlington, VT

- Tractor

- Kubota '2003' L3000DT 8/4 std, engine/pto hp 32.1/27.5, hyd 6.9 gal/min

For anyone interested, this is my winter project.

My property in VT is very steep and comes with the usual honeysuckle, saplings and wild grape vines. I hope this thing will reach over barb wire fences also.

Making sure the weight is kept down to limit the need for counter weight, the project begins.

Starting with an old iron JD 30" mower deck with 28" blade. After all the usual trial and error bugs are worked out of this thing, if the mower deck proves not worthy than I'll rebuild the deck. The tractor/ BH arm test was better than expected. The tractor had no tipping or stress issues at all. I am a little concerned about the stress on the curl piston on the arm.

My BH is powered off remotes rather than a pto pump. The only negative was the levers on the BH were jumpy with the mower fully extended. I think installing flow restrictions on quick connectors while using mower will help.

As you can see, this unit is not powered yet. I have asked for help from the Guru's on the hydraulic forum about a hydraulic motor for power.

To jump off topic for a minute, I plan on adding a 3 spool valve above my loader valve for remotes. I will be putting a grapple on the front and that leaves me two more remotes to the back for TnT.

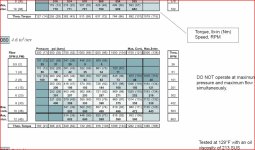

Back to the project. I was told the 6.9 gpm and only approx. 14 hp left for torque out of 30 hp motor was far less than was needed for any blade tip speed. However, The feed back was assuming the Hyd pump would turn the blade directly. This is not the case. I intend on off setting the motor from the blade shalt to allow for a sacrificial belt and the ability of stepping up blade tip speed. I was very grateful for the input but I could not get a response on that scenario. I am unsure on the math and have little knowledge about hydraulic systems. Please help!

That led me to think of adding a pto pump which I was told would now give me closer to 20 gpm. A lot of money to spend you might say. Well here's the other issue; my BH working off the remotes is mediocre at best. All I here all day is the relief squeal. I have owned a little Terrimite rental BH for 20 years and it would out dig my Woods 750 all day long powered by only a 18 hp Briggs. So, the boom will not be used very often once I get my property manageable and apply herbicides. At that time I would switch my pump over to operate the BH for (hopefully) much better performance.

Then again part of me thinks; put a lawn mower engine in it and move on. The problem with that of coarse is oil starvation. the deck will only be able to be tilted slightly.

I would greatly appreciate any and all input and advice.

Thanks, Neal

My property in VT is very steep and comes with the usual honeysuckle, saplings and wild grape vines. I hope this thing will reach over barb wire fences also.

Making sure the weight is kept down to limit the need for counter weight, the project begins.

Starting with an old iron JD 30" mower deck with 28" blade. After all the usual trial and error bugs are worked out of this thing, if the mower deck proves not worthy than I'll rebuild the deck. The tractor/ BH arm test was better than expected. The tractor had no tipping or stress issues at all. I am a little concerned about the stress on the curl piston on the arm.

My BH is powered off remotes rather than a pto pump. The only negative was the levers on the BH were jumpy with the mower fully extended. I think installing flow restrictions on quick connectors while using mower will help.

As you can see, this unit is not powered yet. I have asked for help from the Guru's on the hydraulic forum about a hydraulic motor for power.

To jump off topic for a minute, I plan on adding a 3 spool valve above my loader valve for remotes. I will be putting a grapple on the front and that leaves me two more remotes to the back for TnT.

Back to the project. I was told the 6.9 gpm and only approx. 14 hp left for torque out of 30 hp motor was far less than was needed for any blade tip speed. However, The feed back was assuming the Hyd pump would turn the blade directly. This is not the case. I intend on off setting the motor from the blade shalt to allow for a sacrificial belt and the ability of stepping up blade tip speed. I was very grateful for the input but I could not get a response on that scenario. I am unsure on the math and have little knowledge about hydraulic systems. Please help!

That led me to think of adding a pto pump which I was told would now give me closer to 20 gpm. A lot of money to spend you might say. Well here's the other issue; my BH working off the remotes is mediocre at best. All I here all day is the relief squeal. I have owned a little Terrimite rental BH for 20 years and it would out dig my Woods 750 all day long powered by only a 18 hp Briggs. So, the boom will not be used very often once I get my property manageable and apply herbicides. At that time I would switch my pump over to operate the BH for (hopefully) much better performance.

Then again part of me thinks; put a lawn mower engine in it and move on. The problem with that of coarse is oil starvation. the deck will only be able to be tilted slightly.

I would greatly appreciate any and all input and advice.

Thanks, Neal