wow! talk about a large DISC!

i realize ya asking about other things... but man. first thing that caught me was. is it actually tested. to keep flex down to a min. so when ya out there mowing. the outer edge of the disc does not bow up or down.

second thing that hit me was. do you have the knifes / blades on correctly. what i mean by that is. when the disc spins. will it create the wanted "suction force" to lift grass up to cut it.

i wouldn't think it would matter if knifes / blades were on top or on bottom of disc. just as long as you set them up to cut in correct direction. and created the suction to lift the grass up to be cut. i would imagine being able to place them on top or on bottom of disc. could help you shoot for a higher or lower cut grass. then again i maybe total wrong.

with others scalping,... errr so big of a disc / mowing area. a little hill and all you would have left is dirt on top of that little hill.

=================

if you originally had a square sheet piece of metal. to cut out that large disc. it might be simplier. to measure out a center. drill a hole. through metal. then insert a bolt and tighten it up. with length of bolt sticking up. then hooked a string to bolt. and on other end of string hooked taped a penicl to were you wanted the edge of disc to be cut out. you could make a nice perfect circle.

though with that big of disc. i would imagine. ya initially rough cutting the disc out, and then coming back with a finer detailed metal saw to get a nice clean edge right on the pencil mark. and perhaps taking a grinder and going around outside edges to taking off any sharp edges.

i would imagine after disc is done being cut out and edge work done. string is removed and a good nice straight edge is used (torpedo level for example) and placed up against bolt. to get inital start line done. ((take a pencil and draw clear across the top of disc.))

then move straight edge to other side of bolt. and measure at both ends between line you just drew and straight edge. so both ends are nice and even. and draw another line clear across top of disc.

between the 2 lines. marks the edges of bolt holes for 2 of the knives for blades.

in order to get the remaining 4 knives / blades. you would need to get (duh forgot name of tool) to measure angles. and do a 60 degree angle off of center of bolt. and inital lines you drew.

i got 60 degrees from. there is 360 degrees in a circle. you have 6 knives 360 / 6 = 60 degree spacing from center point between each knife / blade.

once you have your lines drawn out. you can then measure from the outside edge of the disc in. to figure out were the holes need togo for each knife.

once that is all done, then you can drill / cut the center main hole out. using the hole you initally used as a pilot hole for perhaps a whole saw metal bit. if not using that then do same you did to cut disc out, and use a string around bolt. and a pencil taped to end of string to create a nice circle around the center.

once that main big hole in center is done. then measure the inital hole to mounting the disc on. and drill that first. then put a screw in and fasten it onto the drum/deck. so everything is aligned. then use a pencil and/or marker to push through holes and mark the other holes out. ((note got a sharp point ice pick or *duh what is the name of it* to tap with a hammer in each hole. to help ya better identify were center of each hole is. then remove disc and drill the other remaining attachment holes.

===================

above is most likely what i would do making this thing from scratch.

since you already have the disc cut out and that big hole cut out in the center. i might take a piece of plywood. some screws and washers. and fassten the plywood over the main large hole in center. and with multi trial and errors. tap a nail into plywood some. and use a string with a peice of tape on end. till ya found center of the disc. once found tap nail in little further so it holds a little better, double check again you have center of the disc. and ((repeat all steps above. for cutting out disc, ((making it smaller)))), and everything.

==================

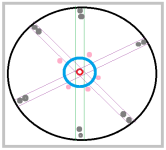

diagram is not the best, and i didn't label things. but hopefully looking back and forth of my notes above. and you should be able to see the lines i noted about drawing. and 60 degree angle between each of the 6 knifes / blades.

if anything it might help ya figure out how to measure or align things to get the disc to work for ya.