LD1

Epic Contributor

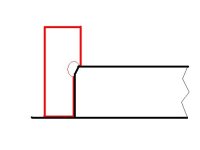

Looking for the best method/style of connection for attaching the wedge to the beam on my upcoming splitter project.

Not looking for type of rod, style of welding, or any of that. Just the type of connection at the joint. Please see attached crappy paint drawing. Black is the 6x6 I-beam and the red is the splitter wedge. The Wedge is going to be 1" thick by 6" wide steel by whatever height I need depending on style.

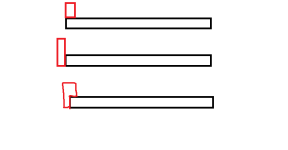

Top is just sitting on top of beam

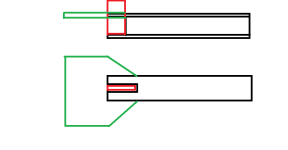

Middle is on back of beam

Bottom is notched with a little weld on both.

So what is the best/strongest method of attaching? or does it likely not matter with a small 4"/~18 ton cylinder??

Not looking for type of rod, style of welding, or any of that. Just the type of connection at the joint. Please see attached crappy paint drawing. Black is the 6x6 I-beam and the red is the splitter wedge. The Wedge is going to be 1" thick by 6" wide steel by whatever height I need depending on style.

Top is just sitting on top of beam

Middle is on back of beam

Bottom is notched with a little weld on both.

So what is the best/strongest method of attaching? or does it likely not matter with a small 4"/~18 ton cylinder??