The pick points on the spreader beam remain in the solid plate no welding effects the piece with the holes. Welding is done on the ends of the beam which is under compression. When you are picking. I do like the third attachment method as long as you can slip a 4-way over it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Attaching wedge to beam: Best method??

- Thread starter LD1

- Start date

- Views: 12221

More options

Who Replied?

/ Attaching wedge to beam: Best method??

#11

LD1

Epic Contributor

Well, now it sounds like I have to decide if I want to take the easy way and do option 3, or take the time to do it like shield arc posted?? Same material either way. Not that it matters as I have a 20' stick of 1"x6".

Grsthegreat: I am in visioning it working lots better. For starters, the wedge will be taller than ones like the super split. Likely around 10" tall. And there will be a short table aft the wedge. So ones that need split again can be slid right around to go again.

If you watch any of the YouTube videos of the ss or Dr inertia splitters, that is basically how this will work, but with a taller wedge and fast hydraulics.

Grsthegreat: I am in visioning it working lots better. For starters, the wedge will be taller than ones like the super split. Likely around 10" tall. And there will be a short table aft the wedge. So ones that need split again can be slid right around to go again.

If you watch any of the YouTube videos of the ss or Dr inertia splitters, that is basically how this will work, but with a taller wedge and fast hydraulics.

yomax4

Elite Member

- Joined

- Mar 11, 2007

- Messages

- 2,847

- Location

- Midwest

- Tractor

- ISEKI TA 247. Stihl Saws Gravely Zt's Polaris ATV's State Of The Art Welding Equipment

You could do # 1 with #2 behind it. Or # 3.. Both will work. When you get your wedge failures is mostly when you add height to the wedge. I never had any issues with an 8" wedge no matter how it was sitting in the I beam. when I turned it into a 12" wedge it would tear off unless I did a 1-2 combo or #3. Also as much as I hate to admit it. It held best when welded with 8018 as compared to Pulsed Mig..

Arc weld

Veteran Member

You could do it like the 3rd picture and put fish plates inside the I beam extending on to the wedge. If you wanted to get really fancy, you could cut the I beam and the wedge on a 45 deg. angle and do it like the 3rd pic. Then you'd get a lot more weld. You could even leave the flange longer on the bottom to put some nice fillet welds on the wedge and the bottom flange. Probably overkill but you'd never have to worry about it breaking.

Arc weld

Veteran Member

I would go with the 3rd / bottom drawing. Or cut a hole in the top flange of the beam, cut out the web. Insert the wedge in the hole. This way you get a lot of weld volume. You can leave 1 or 2-inch of beam behind the wedge also.

I did this for the pad eyes on my bridge crane.

I'm :shocked: Maybe I'm seeing things but it looks like there's a couple of flaws on that pad eye. Top left and lower right. You might have downgrade the 80 ton rating... to about 79.5 tons.:laughing:

Shield Arc

Super Member

I seen that too after taken the picture years ago to post on one of the welding forums. I went back out to the shop to look. It is just the picture. For me it's a lot easier to weld than take a good picture! :confused3:

Shield Arc

Super Member

I like Arc weld's idea of notching the top flange and web back, let the bottom flange run under the wedge to get a full fillet weld! I'm wondering in this case if it would help to take a hole saw and cut a 1 1/2 to 2-inch circle in the inside 90-degree corner? Or just leave it 90-degrees and get a full fillet weld?:confused3:

I'm always interested in different joint designs!

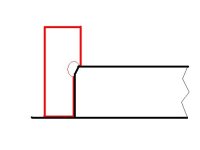

Please forgive my quick and dirty MS Paint drawing, hopefully you get the idea of what I'm trying to say.

hopefully you get the idea of what I'm trying to say.

I'm always interested in different joint designs!

Please forgive my quick and dirty MS Paint drawing,

Attachments

LD1

Epic Contributor

I like Arc weld's idea of notching the top flange and web back, let the bottom flange run under the wedge to get a full fillet weld!

Thats what I am starting to think. Allthough, I would also consider leaving the top flange full length also, kinda like your first idea, but no webbing behind the wedge. Cause I do plan on adding a table anyway. So no point in cutting out metal (top web) just to add it back later in the form of a table.

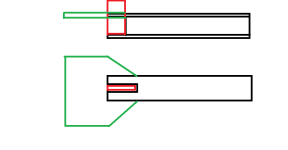

Here is a crappy MSpaint drawing. Black is beam, Red is wedge, and Green being table.

Shield Arc

Super Member

That's a really good idea too!:thumbsup: Look at all the weld volume you get there.

I like the table idea too. Wonder if it should be bigger, or at least lips on the outside edges to catch the wood from falling?

I like the table idea too. Wonder if it should be bigger, or at least lips on the outside edges to catch the wood from falling?

LD1

Epic Contributor

That's a really good idea too!:thumbsup: Look at all the weld volume you get there.

I like the table idea too. Wonder if it should be bigger, or at least lips on the outside edges to catch the wood from falling?

The drawing is really not to scale. But I dont want lips on the end as I want the split pieces to fall off the table. The only ones I dont want to fall off are the ones that need split again. But once splitdown to the right size, I want the next round I put on there to push those pieces off the table. So no lip on the end, but maybe on the sides??

Watch this video of a supersplit inertia.

https://www.youtube.com/watch?v=V95e-sMQTL8

Thats how I invision splitting wood. Similar table and wedge. Only with Hydraulics that will be a touch slower than that inertia.