brain55

Veteran Member

Cool! Looks good. Couple of questions from one who knows less than nothing about metals/welding/hydraulics...

The existing QD's on the dip stick were already there? For a thumb?

You welded the filler plate in between the sides of the dipper stick. When I installed my thumb, albeit much smaller scale, on my tractor, I was given a plate/cylinder bracket for the cylinder top mount which spanned the dipper and was welded at the side plate edges of the dipper and not across the dipper at the top and bottom of the plate. And I was told to bring the thumb to the bucket, and not to bring the bucket to the thumb, even though the cylinders have the same pressure ratings. My circuit(s) for the thumb/bucket don't have overload pressure reliefs built in, or adjustable to my knowledge, could this account for the bringing bucket to thumb method on the ex?

How long did it take to do the job, and what was the final cost, if you don't mind saying?

One last Q: your username is brain55, but your name is Brian? I'm confused, was that intentional?:confused3:

Thanks for any answers you care to share:thumbsup:

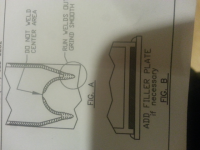

You may be able to see in this pic how the edges off the arm are higher than the surface.

My mount was the same width as the arm. If I had welded the mount to the arm without the filler plate there would have been nearly a 1/2" gap between the mount and the arm. They were very specific on how to weld the mount ends. I think in this picture you can see the fish tails on the mount.

The auxiliary hydraulics could have been for anything. A hammer, drill, etc.

I would say that the recommendation of bring the thumb to the bucket is good if you don't have circuit reliefs. This guy at some point will have operators on this machine that wouldn't comprehend that, so it is better that I checked and lowered the overload pressure. Not to mention the manufacturer of the thumb was also quite clear on this too for warranty reasons.

Brain is a nickname from my best friend while I was crew-checking his dragsters. Besides plenty of people spelling it wrong anyway.

Brian