Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,311

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

It would be great to hear from someone with actual experience using "normal generators" for welding. I am a hobby/maintenance welder, don't need pro-level eqpt, just need it to work for the occasions when I need the 1/4" & thicker settings. If I were to guess - I would need it to work for 2 hours per year for 20 years (without consuming funds that I could use for other tools & stuff! )

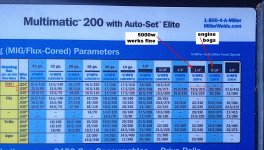

I tried to run the MultiMatic 200 off a 5000W (21A) generator and it could only push the 1/4" thickness preset (on 230v).

I tried to run the MultiMatic 200 off a 5000W (21A) generator and it could only push the 1/4" thickness preset (on 230v).

Attachments

Last edited: