MinnesotaDaveChalmers

Platinum Member

You're very welcome guys - hope the info helps

After a while, a guy tends to make the small adjustments kind of automatically just based on how the puddle and arc are behaving themselves

Very nice testing - you can clearly see where the root that wasn't fully fused started splitting apart, but the fused part stayed together. Nicely done

Over time, the cracks that start in the non-fused part tend to "zipper" through the rest.

It generally takes a very long time - but if well hidden tend to let go without warning.

Many of have seen this when we analize a broken item that comes in and the 6" crack is rusted all the way except the last 1" that suddenly broke the rest of the way.

If I had any advise, I'd try making that cover pass in two or three smaller beads - on the screen it looks as if your machine had a hard time carrying a bead that wide. No way to tell from my couch of course - you'd be the only one who could see it as it went in.

Any way you could do a face bend of one of the other welds to see if the cover pass stays together, splits in the middle, or pulls away from the bevel?

After a while, a guy tends to make the small adjustments kind of automatically just based on how the puddle and arc are behaving themselves

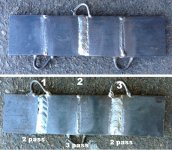

OK here's how the 3/8 thick test plate (welded with 120v) bent.

I bent only weld#2, the weld discussed earlier. It was very strong, had to reef on that 20T press to bend it to the 90-ish deg as shown.

From what I can see looking at weld #2 it's pretty obvious that:

---> #1 will be weaker

---> #3 will be stronger

But even though weld #2 was not 100%, it would not let trailer parts loose on the highway, it was firkin' strong.

Very nice testing - you can clearly see where the root that wasn't fully fused started splitting apart, but the fused part stayed together. Nicely done

Over time, the cracks that start in the non-fused part tend to "zipper" through the rest.

It generally takes a very long time - but if well hidden tend to let go without warning.

Many of have seen this when we analize a broken item that comes in and the 6" crack is rusted all the way except the last 1" that suddenly broke the rest of the way.

If I had any advise, I'd try making that cover pass in two or three smaller beads - on the screen it looks as if your machine had a hard time carrying a bead that wide. No way to tell from my couch of course - you'd be the only one who could see it as it went in.

Any way you could do a face bend of one of the other welds to see if the cover pass stays together, splits in the middle, or pulls away from the bevel?