richfranklin

New member

I have a k46 but how do you get the vent off with out ripping the ruber to fill with oil

I was able to gently work it our after I had split the case. However, I'm pretty sure they included a new one in the rebuild kit.

I have a k46 but how do you get the vent off with out ripping the ruber to fill with oil

I have a k46 but how do you get the vent off with out ripping the ruber to fill with oil

It is just press fit on, gently pry up on the edges with a thin tool. I used my pocket knife being careful not to cut it.

I don't know why I assumed I had a K46. But I don't. I have a T40J. I don't think that much matters as the plan of attack should be the same. But I wanted to verify that with the more knowledgeable than me. Are the 2 trannys the same? Or should I be ordering specifically T40 parts from the infamous Derrick Dalton? Thanks in advance!

Now I'm in the difficult decision on whether to spend another $376.64 + shipping on another pump & motor rebuild kit (Tuff Torq doesn't even allow you to buy the parts separately online anymore), replace the whole K46 with a new unit for $500+ (Ebay), or start shopping (and financing) a new garden tractor with a real trans.

Where do you get that notion? I've got separate T40 parts in my shopping cart as we speak. And I just checked on K46 parts and they can be added too. Am I doing something wrong?

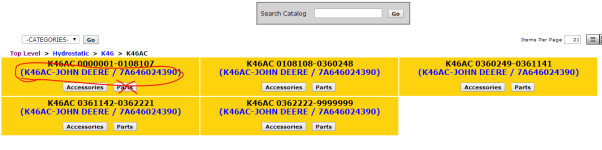

This is what I get from my K46AC shopping screen:

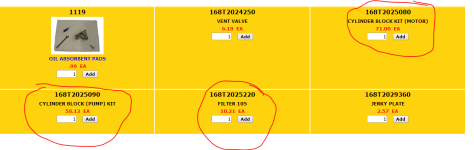

View attachment 388810View attachment 388812

They removed the Add button next to select items including the pump, motor, & case.