MossRoad

Super Moderator

- Joined

- Aug 31, 2001

- Messages

- 65,366

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

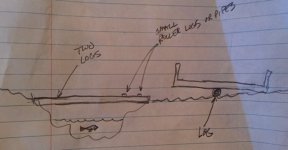

Thanks for all the input, I worked my numbers out from center toward the ends, 4' = 1000lbs. If the axle is carrying 9k at 24' then all that is left for the "tongue" weight is 1000lbs. At this point I figured there has to be a formula. I do need to know the axle weight and the tongue weight to insure they are within my tractors lifting ability and the axle rating. What really concerns me is the effect on the balance during the move, I guess I could use some light rope to secure to the FEL for some control but if things really go south the rope would break and the 10K bridge can go where it wants without me and the tractor attached. Then I will call the crane company

You've got 6000 pounds in front of the axle and 4000 pounds behind the axle. Yes, the axle is carrying most of the weight. And the 16' behind the axle with 4000# on it balances out the first 16' and 4000# in front of the axle. But you have an additional 2000# that starts 16' in front of the axle and goes 8 more feet towards the front of the trailer.

So now you basically have a 2000# weight hanging 8' in on a 24' long lever. Its going to take 2/3 more force than half the weight. So, 1000# + 667# = 1667# of tongue weight. I think.... :laughing:

Man, where are the people that can do this math for us???? :confused3: