Shield Arc

Super Member

I'm so impressed!:cool2:

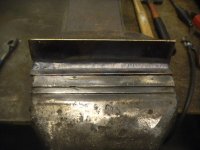

Last spring my brother-n-law bought a PowerArc-200ST from Mark. Last week I was at his place, he said he was having a hard time with the lift arc Tig start. Personally I never liked that method. I prefer high frequency, or scratch start. My brother-n-law is a retired very high end Tig welder. Worked on some of the space shuttles, even welded on nuclear bombs. But he can't say what he was welding on nuclear bombs! I took my PowerArc 300 to his place. Until next spring we traded welders. I brought his PowerArc 200 ST home with me. I was playing with it this morning. I'm so impressed with the way it runs 6010. You control the puddle with arc length!

Remember now I'm no pipe welder, (a union thing).

This little welder runs very hot! With my Lincoln V350-Pro I run 1/8 5P-Plus 6010 around 75-amps. With this welder 60-amps does the same thing.

Last spring my brother-n-law bought a PowerArc-200ST from Mark. Last week I was at his place, he said he was having a hard time with the lift arc Tig start. Personally I never liked that method. I prefer high frequency, or scratch start. My brother-n-law is a retired very high end Tig welder. Worked on some of the space shuttles, even welded on nuclear bombs. But he can't say what he was welding on nuclear bombs! I took my PowerArc 300 to his place. Until next spring we traded welders. I brought his PowerArc 200 ST home with me. I was playing with it this morning. I'm so impressed with the way it runs 6010. You control the puddle with arc length!

Remember now I'm no pipe welder, (a union thing).

This little welder runs very hot! With my Lincoln V350-Pro I run 1/8 5P-Plus 6010 around 75-amps. With this welder 60-amps does the same thing.