air hose is not filled with actual "air" it is completely full of "fluid" most likely some sort of antifreeze / water mixture. perhaps RV antifreeze. fluid is not compressible, air is. big difference.

**see attach diagram to go with below text**

you will most likely need some sort of bleeder valve on both ends of the hose... to bleed out as much air as possible.

the metal pipe, with push rod = a really small little hydraulic cylinder in all idea.

===========

in pond plumbing. you can DIY what is known as a "stand pipe" it works as an on/off valve.

--1. you dremal / sand the outside of a pipe just a little bit down. so it slides easily in/out of the fitting ((most plastic fittings have a angle / taper to them, hence slight sanding to end of pipe))

--2. you put a little "cutting disc" onto dremal or into drill. and put a 2 groves on end of pipe. so both groves are within the fitting when you push pipe into the fitting. the grove does not need to be that deep. just a little grove. enough to hold a 0-ring.

--3. 0-ring rubber pickup at most hardware stores most likely comes in some sort of package with other 0-rings. you want it a little bit tight. TIP: add some vasaline of all things to end of pipe and 0-ring and should roll / slip on fairly easily and at same time give some lubrication.

note: the stand pipe is not a perfect on/off valve. they can slightly drip a little bit of water. at least mine have. though i hacked away at them. not caring much about leakage.

============

OK BLAH BLAH BLAH above... change it up for you....

---see if you can find a metal rod that fits nearly perfectly inside of a pipe (rod just a little smaller than inside of pipe.. talking some were in 1/2" rod diameter maybe slightly bigger to make it easier to deal with 0-rings. within reason. ((never done it before, so just guessing at rod diameter.))

---put a couple groves on end of rod, and slip on a couple o-rings. smear some vasaline on. 0-rings to keep them rubber and keep them from drying out, you have a hydraulic cylinder, now.

---attach bottom of pipe to air hose filled with a fluid..

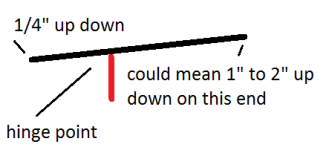

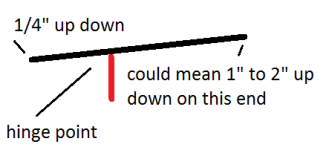

---place rod just below latch, that i can push up. most likely 1/4" difference if that. that the rod might move. might need some sort of lever action. to change 1/4" movement to say 1" movement.

--some were add a Tee (plumbing piece) toss on a valve, and make it so you can easily use a "funnel" to fill things up with water. and bleed air out of the hose. a couple reducers going from say 1/2" up to 3" pipe. can make for a nice DIY funnel built into things.

NOTE: you may need concrete / pavement. or something smooth vs rock/mud for air hose filled with a fluid to work. rock /mud may let the air hose sink down into mud/rock.

NOTE: a larger inside diameter air hose. will cause the DIY hyd cylinder rod to move more up/down.

NOTE: a smaller diameter rod for the DIY cylinder will cause the DIY hyd cylinder rod to move more up/down

================

EDIT: gogole searched for... miniature hydraulic cylinder

and got this for $5.99

SMC Type CDJ2D10 15 Mini Pneumatic Cylinder Double Acting Double Clevis Style | eBay not sure if it would work (did not look close to specs) but for 6 bucks... *shrugs*