You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SSQA fork build

- Thread starter Mysfyt

- Start date

- Views: 36956

More options

Who Replied?

/ SSQA fork build

#41

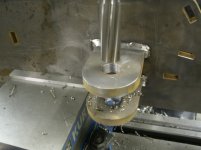

More work on the side plates. Welded the sprocket mounts in place and then bored and reamed them for the pins. Also finished boring the left side plate for the support bar and next up will be indexing and drilling and tapping the holes for the cap plates. Getting pretty close to final fit up and welding.

Attachments

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,042

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

Are you worried about this being too heavy for your tractor to effectively lift? Is it going on the L3901?

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,042

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

He already said that about 4 post up.What welder are you using?

Are you worried about this being too heavy for your tractor to effectively lift? Is it going on the L3901?

Yes, its going on my L3901. I know the lift capacity will be limited to around 800 lbs give or take, but that will take care of most my needs. I have a 1000 lb manual fork lift in my shop and so far that has handled everything I needed to move around.

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,042

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

countrybumpkin

Elite Member

- Joined

- Jun 14, 2005

- Messages

- 3,248

- Tractor

- Kioti, kubota

I'm really curios too what the finished set of forks weigh, looks like the specs show about 855 lbs at 19.6" from the pins. May just be a good reason to upgrade the tractor to match the forks.  Very nice work.

Very nice work.

jimmysisson

Veteran Member

- Joined

- Jul 11, 2005

- Messages

- 2,358

- Location

- W.Mass

- Tractor

- 1993 NH 2120 (the best), 1974 MF 135 (sold, but solid), 1947 Farmall A (bought, sold, bought back, sold again), 1956 MH50 lbt (sold, in 1980, darn it)

What dia is the rod they slide on? Mine is I think 1-1/2" and is about 2 ft. long: each side separate. I've managed to bend one, w 4' long forks, doing what I don't remember.

I hope the chain equalizer doesn't want to bind up the sideways action, being a ways from the cylinder c/l. Probably worse as they get gunked up. (Probably not too gunky, though, judging by the welding!) Mine slide by hand too easily if greased, too hard if not. They live inside.

You do very nice work.

Jim

I hope the chain equalizer doesn't want to bind up the sideways action, being a ways from the cylinder c/l. Probably worse as they get gunked up. (Probably not too gunky, though, judging by the welding!) Mine slide by hand too easily if greased, too hard if not. They live inside.

You do very nice work.

Jim

Woops didn't see it! I was fascinated by the quality and have been considering a tig setup.He already said that about 4 post up.

Jim Timber

Veteran Member

The power supply he's got is an earlier version of mine. They could be had used for not much more (if any?) than a comparable single piece MIG machine in the 250A class when I got it, but you'll also need a feeder and that can sometimes be expensive unless you find a deal on one.

I love my Invision 354MP. Even without utilizing the pulse capabilities, it's one of the nicest arcs I've had the fortune to run, let alone owning it. Since I bought mine in the 2008 sell-off, I'm not sure what they go for today. New ones are mid 4 figures.

Still takes a steady hand to run a bead like that. Been appreciating the build Mysfyt!

Been appreciating the build Mysfyt!

I love my Invision 354MP. Even without utilizing the pulse capabilities, it's one of the nicest arcs I've had the fortune to run, let alone owning it. Since I bought mine in the 2008 sell-off, I'm not sure what they go for today. New ones are mid 4 figures.

Still takes a steady hand to run a bead like that.

Thanks! The support bar is 2-1/2" hardened and chromed round from Alro steel. They had a drop that was 68" long so I'll have about 24" left over for another project. They list it as 100 ksi yield.What dia is the rod they slide on? Mine is I think 1-1/2" and is about 2 ft. long: each side separate. I've managed to bend one, w 4' long forks, doing what I don't remember.

I hope the chain equalizer doesn't want to bind up the sideways action, being a ways from the cylinder c/l. Probably worse as they get gunked up. (Probably not too gunky, though, judging by the welding!) Mine slide by hand too easily if greased, too hard if not. They live inside.

You do very nice work.

Jim

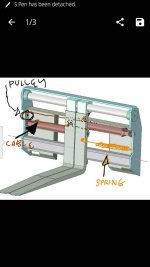

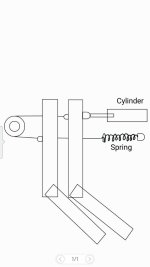

What about putting the cylinder pushing left on the left fork and connect that fork to a cable to a pulley fastened to the right hand side of the frame where the cable run through the pulley and connects to the right fork. That way, when you spread the forks apart the hydraulic and the cable pulls them apart. Using a spring under tension between the right fork and left frame wall will pull it closed while the hydraulic pulls the left one closed.

davedj1

Veteran Member

Sounds interesting. Any pictures or links for reference?

I don't, just a design in my head but basically the cylinder would be more or less horizontal pushing one of the arms while a solid piece goes back over to push/pull the other side. Maybe an S shape piece in the middle with a short cylinder?

I could maybe draw/sketch up something if you need me to, not on cad though...LOL

here is another idea similar to someones idea above: https://www.kaup.de/en/products/kaup-attachments/productdetail/fork-positioners/product/t163sn.html

Attachments

(Quote)Still takes a steady hand to run a bead like that. Been appreciating the build Mysfyt!

Thanks! As far as the welding goes, what you're seeing on the larger welds is flux core (dual shield). IMHO it is the most forgiving welding process there is. On the round that I welded, I was assisted by a positioner. Get your speed set, pull the trigger and the biggest challenge is to not fall asleep. I use .052 diameter because I just seem to get along best with that size. Used to run .045 on my Miller 250 and it worked great, but you had to watch for undercut. I use straight Co2 btw.

This stuff would just love your 354. Give it a try sometime( if you haven't already). Does your welder run off single or 3 phase?

Thanks! As far as the welding goes, what you're seeing on the larger welds is flux core (dual shield). IMHO it is the most forgiving welding process there is. On the round that I welded, I was assisted by a positioner. Get your speed set, pull the trigger and the biggest challenge is to not fall asleep. I use .052 diameter because I just seem to get along best with that size. Used to run .045 on my Miller 250 and it worked great, but you had to watch for undercut. I use straight Co2 btw.

This stuff would just love your 354. Give it a try sometime( if you haven't already). Does your welder run off single or 3 phase?

Last edited: